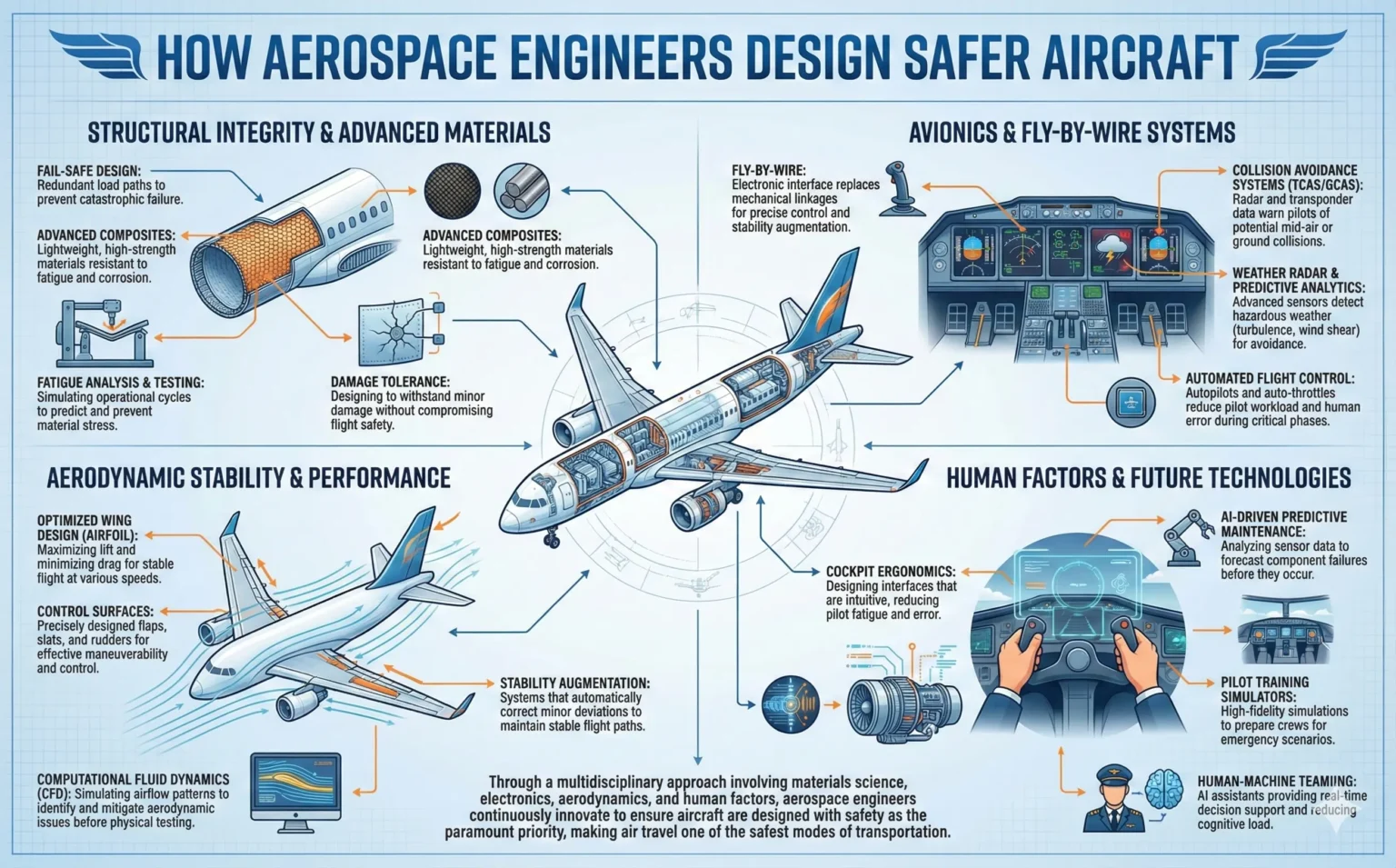

Aviation has transformed the world, shrinking distances and connecting people like never before. Yet, behind every smooth takeoff and gentle landing lies a meticulous science dedicated to one overriding goal: safety. Aerospace engineers, the unsung architects of the skies, pour years of expertise into crafting aircraft that not only soar efficiently but also withstand the unpredictable forces of flight. With global air travel carrying billions of passengers annually and accident rates plummeting to historic lows—thanks to innovations that have made flying safer than driving—it’s clear that thoughtful design is the backbone of this progress.

This article dives deep into how these engineers approach safety, from selecting resilient materials to integrating smart avionics, drawing on proven principles and real-world examples to illustrate a process that’s as fascinating as it is rigorous.

Table of Contents

The Foundations of Aircraft Safety Design

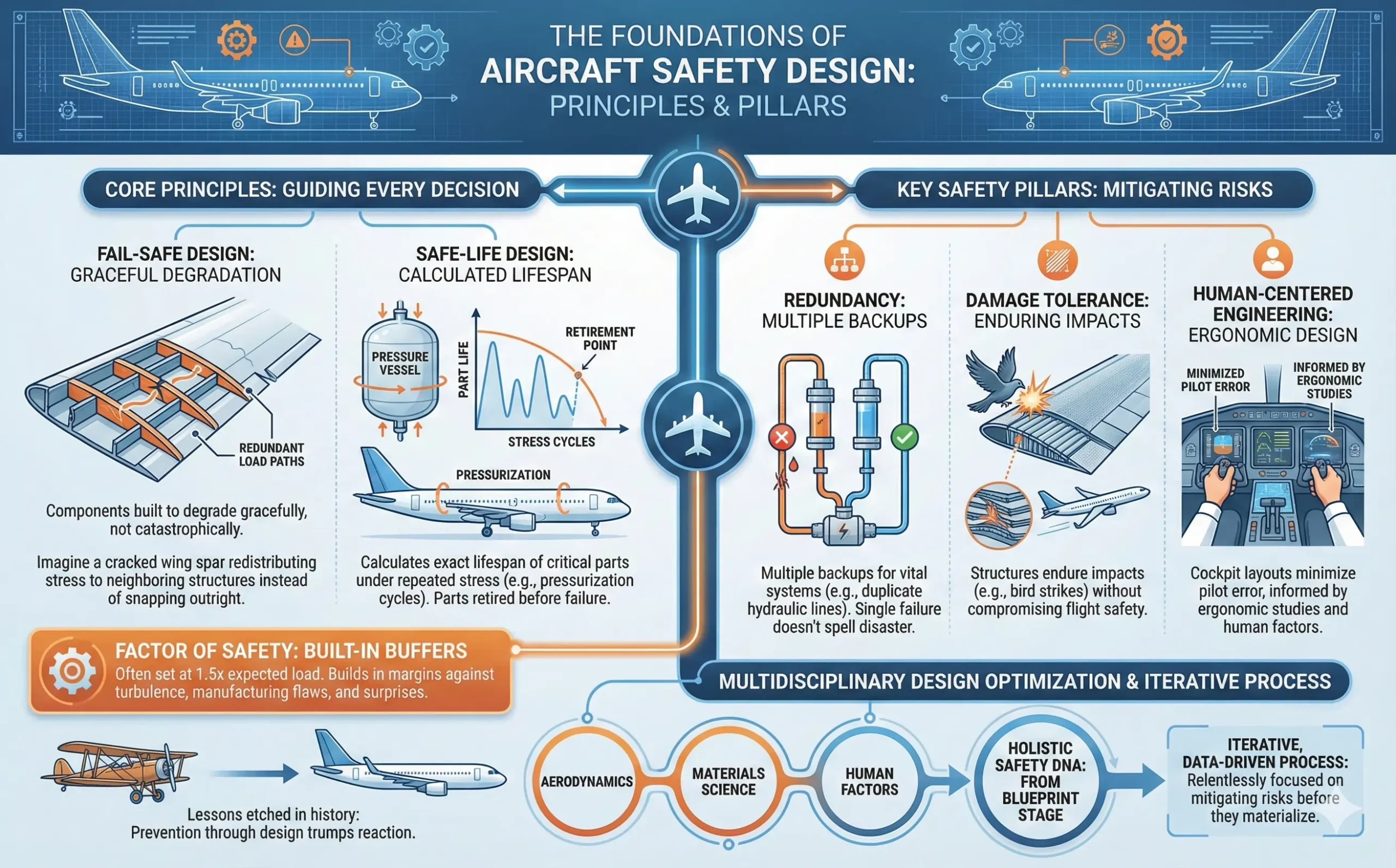

Safer aircraft lies a set of core principles that guide every decision, ensuring that even in the face of failure, lives are protected. Aerospace engineers start with the concept of fail-safe design, where components are built to degrade gracefully rather than catastrophically. Imagine a wing spar that, if cracked, redistributes stress to neighboring structures instead of snapping outright—this isn’t science fiction but a deliberate engineering choice honed over decades.

Complementing this is the safe-life design approach, which calculates the exact lifespan of critical parts under repeated stress, like the endless cycles of pressurization during flights. Engineers use factor of safety metrics, often set at 1.5 times the expected load, to build in buffers against surprises such as turbulence or manufacturing flaws. These principles aren’t arbitrary; they’re born from lessons etched in history, where early aviation mishaps taught the industry that prevention through design trumps reaction every time.

To bring these ideas to life, consider the evolution from wood-and-fabric biplanes to today’s composite marvels. Engineers now employ multidisciplinary design optimization, blending aerodynamics, materials science, and human factors into a cohesive whole. This holistic view ensures that safety isn’t an add-on but woven into the aircraft’s DNA from the blueprint stage.

- Key Safety Pillars:

- Redundancy: Multiple backups for vital systems, such as duplicate hydraulic lines, ensure that a single leak doesn’t spell disaster.

- Damage Tolerance: Structures that can endure impacts, such as bird strikes, without compromising flight.

- Human-Centered Engineering: Cockpit layouts that minimize pilot error, informed by ergonomic studies.

These foundations set the stage for a design process that’s iterative, data-driven, and relentlessly focused on mitigating risks before they materialize.

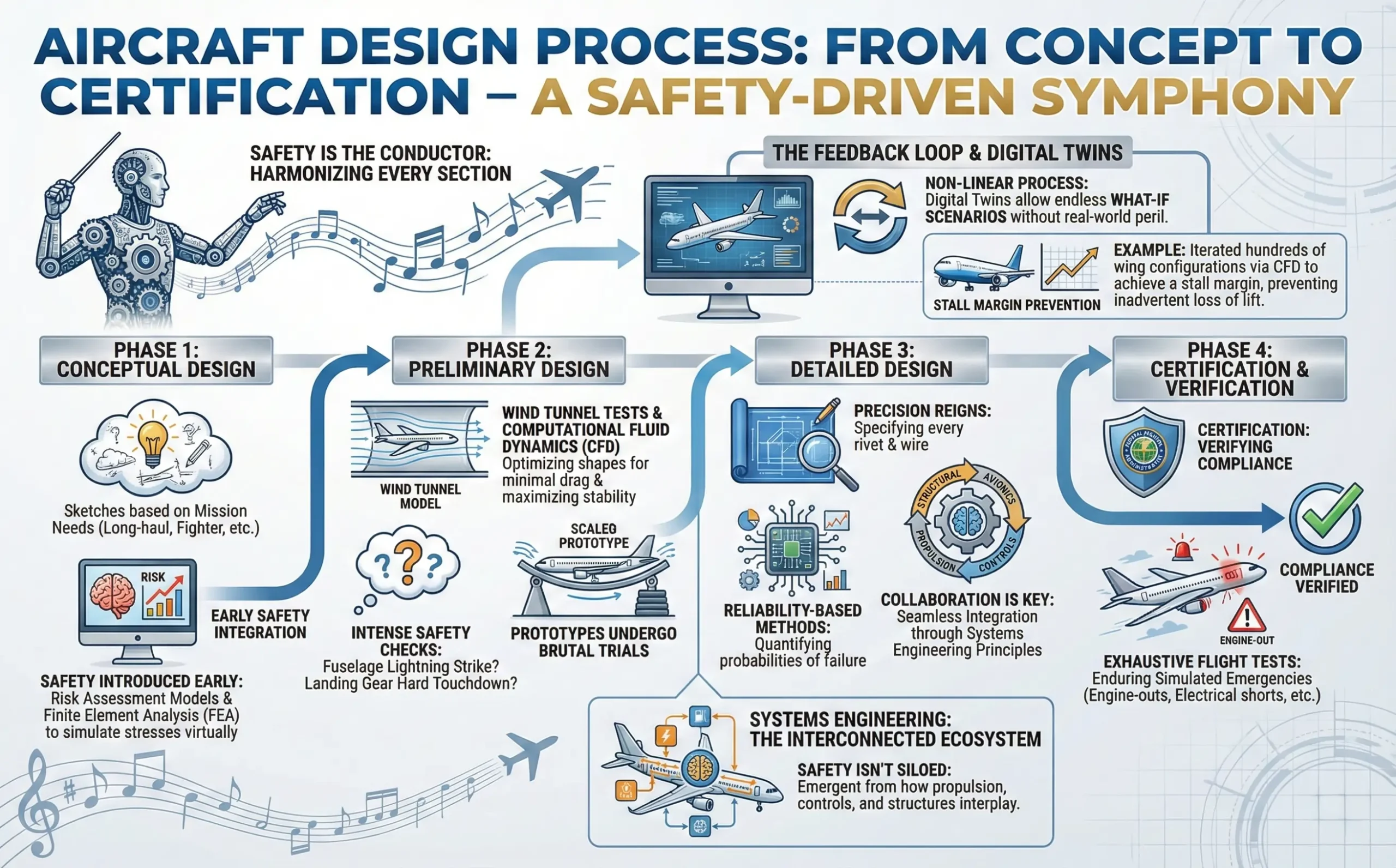

The Step-by-Step Design Process: From Concept to Certification

Designing an aircraft is like composing a symphony—each section must harmonize perfectly, with safety as the conductor. The journey begins in the conceptual design phase, where engineers sketch broad outlines based on mission needs, such as long-haul passenger jets or agile fighters. Here, safety is introduced early through risk assessment models, which predict potential failure modes using tools like finite element analysis to simulate stresses virtually.

Moving to preliminary design, teams refine these ideas with wind tunnel tests and computational fluid dynamics (CFD) software, optimizing shapes for minimal drag while maximizing stability. Safety checks intensify: Will the fuselage withstand a lightning strike? Can the landing gear absorb a hard touchdown at maximum weight? Prototypes, often scaled models, undergo brutal trials to validate assumptions.

The detailed design phase is where precision reigns. Engineers specify every rivet and wire, incorporating reliability-based methods that quantify probabilities of failure. Collaboration is key—structural experts consult with avionics specialists to ensure seamless integration. Finally, certification by regulatory bodies verifies compliance, involving exhaustive flight tests where aircraft endure simulated emergencies, from engine-outs to electrical shorts.

This phased approach isn’t linear; it’s a loop of feedback, with digital twins—virtual replicas—allowing endless what-if scenarios without real-world peril. For instance, during the development of wide-body jets, engineers iterated hundreds of wing configurations via CFD to achieve a stall margin that prevents inadvertent loss of lift, a common culprit in past incidents.

Throughout, systems engineering principles ensure the aircraft functions as an interconnected ecosystem. Safety isn’t siloed; it’s emergent from how propulsion, controls, and structures interplay.

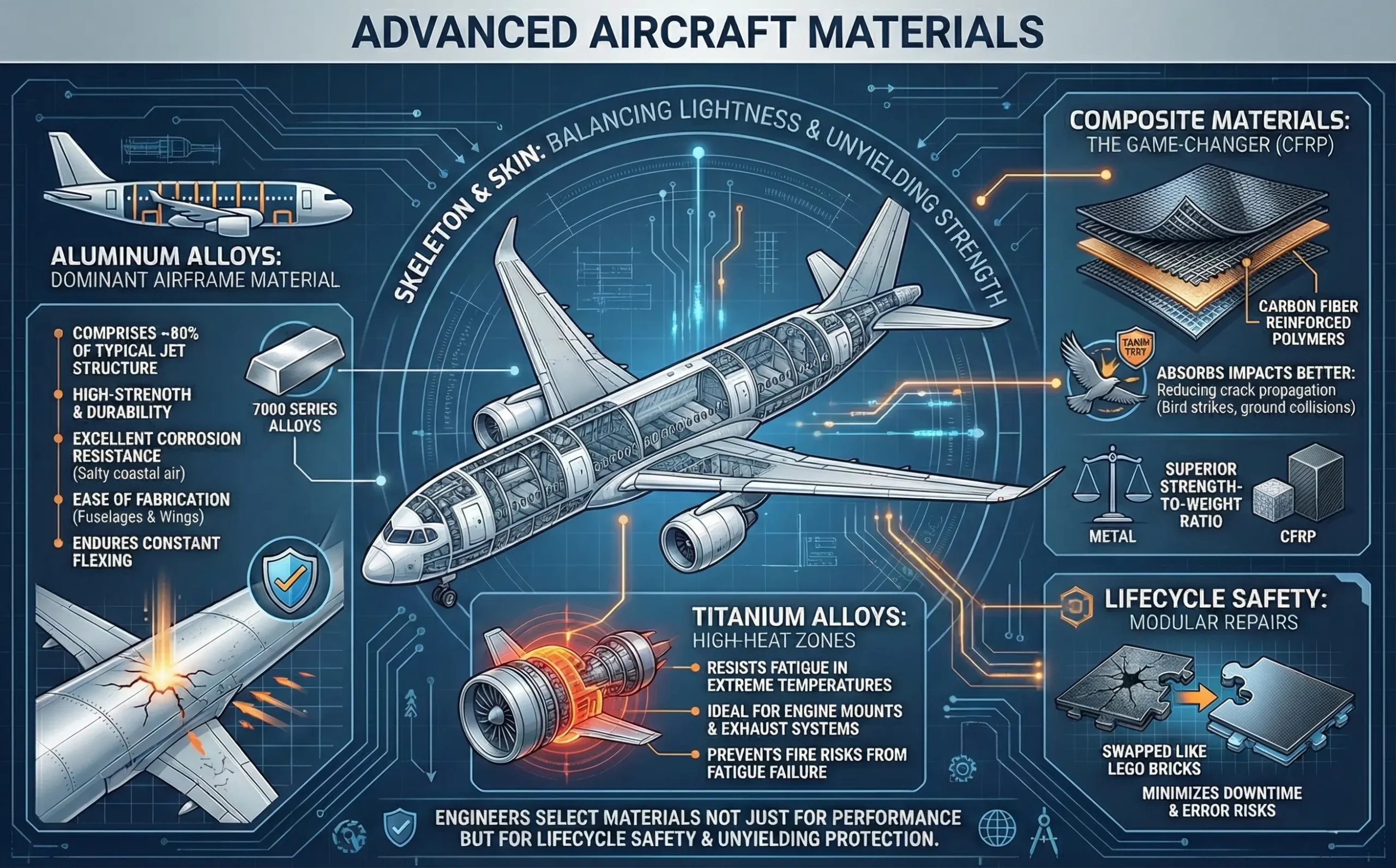

Materials: Building Blocks for Resilience

No discussion of safer aircraft is complete without examining the materials that form their skeleton and skin. Gone are the days of spruce wood and doped canvas; modern designs lean on advanced alloys and composites that balance lightness with unyielding strength. Aluminum alloys, like the high-strength 7000 series, dominate airframes, comprising up to 80% of a typical jet’s weight by structure. Their corrosion resistance and ease of fabrication make them ideal for fuselages that endure salty coastal air and constant flexing.

Yet, the real game-changer is composite materials, such as carbon fiber reinforced polymers (CFRP), which offer a strength-to-weight ratio far superior to metals. These layered wonders absorb impacts better, reducing crack propagation—a boon for bird strikes or ground collisions. Titanium alloys shine in high-heat zones like engine mounts, resisting fatigue that could lead to fires.

Engineers select materials not just for performance but for lifecycle safety. Composites, for example, enable modular repairs, where damaged sections can be swapped like Lego bricks, minimizing downtime and error risks.

To illustrate the trade-offs, here’s a comprehensive comparison table of common aircraft materials:

| Material Type | Key Properties | Primary Uses in Aircraft | Safety Advantages | Drawbacks | Example Applications |

|---|---|---|---|---|---|

| Aluminum Alloys | High strength, lightweight, ductile | Fuselage skin, wing spars | Excellent fatigue resistance, easy to inspect | Susceptible to corrosion if not treated | Boeing 737 fuselage panels |

| Titanium Alloys | Exceptional heat resistance, corrosion-proof | Engine components, landing gear | Withstands extreme temperatures without weakening | High cost, difficult to machine | Jet engine compressor blades |

| Carbon Fiber Composites (CFRP) | Superior stiffness-to-weight, impact absorption | Wings, tail assemblies | Reduces weight for better fuel efficiency and stability | Requires specialized repair techniques | Airbus A350 wing structure |

| Steel Alloys | Ultimate tensile strength, hardness | Undercarriage, fasteners | Handles heavy loads without deformation | Heavier than alternatives, prone to rust | Main landing gear struts |

| Polymer Matrix Composites | Flexible, vibration-dampening | Interior panels, radomes | Lowers noise and vibration for crew comfort | Less durable in fire scenarios | Cabin flooring and sidewalls |

This table underscores how material choice is a calculated gamble, prioritizing safety metrics like ultimate load capacity over mere cost. In practice, hybrid designs—blending metals and composites—emerge as the sweet spot, as seen in next-gen fighters where CFRP wings flex under g-forces without fracturing.

Aerodynamics: Mastering the Invisible Forces

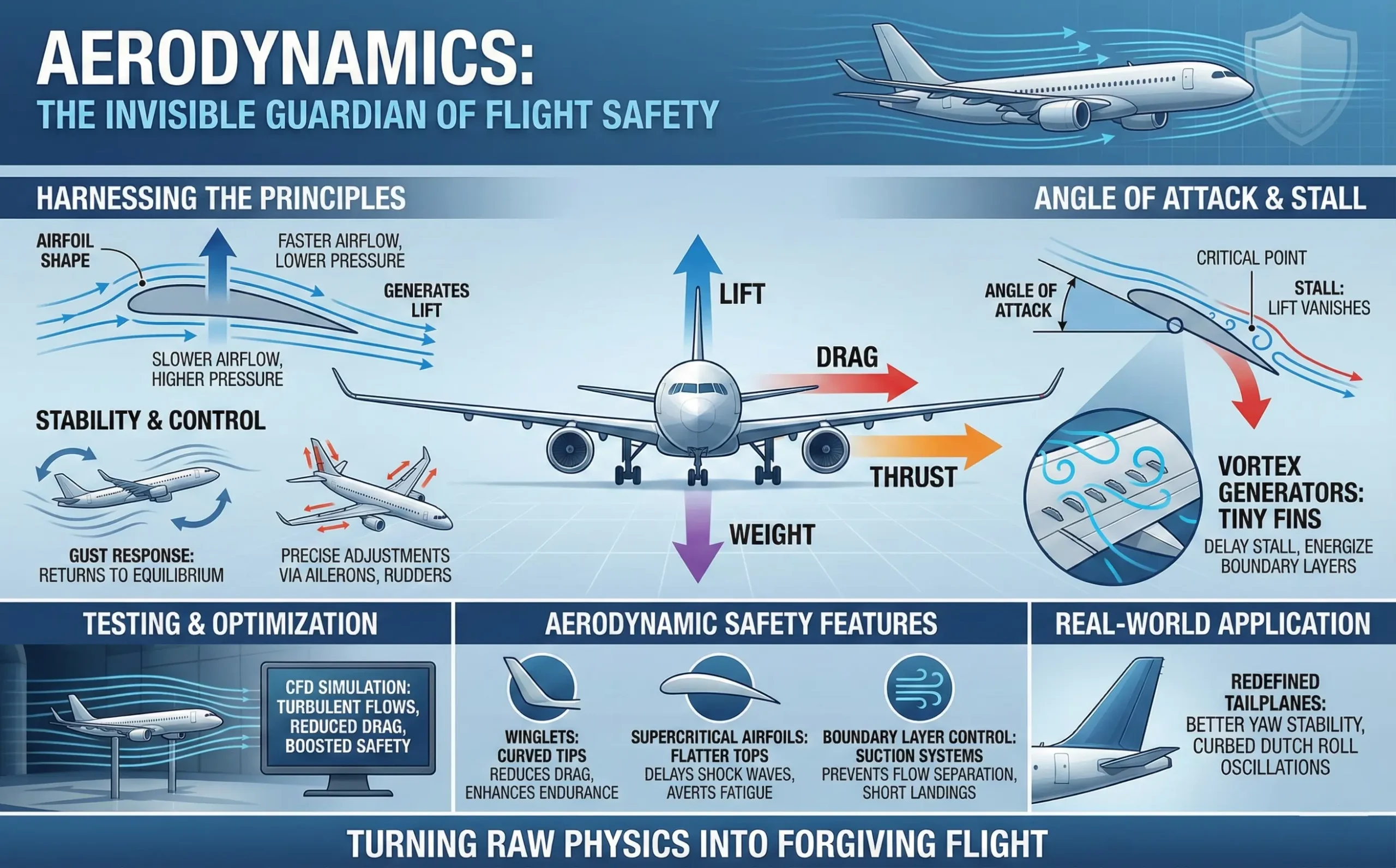

Aerodynamics isn’t just about speed; it’s the invisible hand steering safety through every maneuver. Engineers harness principles of lift, drag, thrust, and weight to craft aircraft that remain predictable, even in chaos. A well-designed wing, with its curved airfoil shape, generates lift by accelerating air over the top surface, creating lower pressure that pulls the plane upward. But safety demands more: stability ensures the aircraft returns to equilibrium after gusts, while control allows precise adjustments via surfaces like ailerons and rudders.

Critical to this is the angle of attack, the tilt between the wing and the oncoming air. Push it too far, and stall occurs—lift vanishes, and the plane drops. Modern designs incorporate vortex generators, tiny fins that delay stall by energizing boundary layers, buying pilots precious seconds in emergencies.

Wind tunnel testing reveals these nuances. For example, during low-speed handling trials, engineers tweak flap deployments to maintain maneuvering margins, preventing spins that plagued early jets. Computational tools now simulate turbulent flows around fuselages, optimizing shapes to slash drag by 20%, indirectly boosting safety by conserving fuel and extending range for diversions.

- Aerodynamic Safety Features:

- Winglets: Curved tips that reduce induced drag and fuel burn, enhancing endurance.

- Supercritical Airfoils: Flatter tops that delay shock waves at high speeds, averting buffet-induced fatigue.

- Boundary Layer Control: Suction systems that prevent flow separation, crucial for short-field landings.

In one notable application, redesigning tailplanes for better yaw stability has curbed Dutch roll oscillations, a subtle weave that once disoriented pilots. Aerodynamics, then, is safety’s silent guardian, turning raw physics into forgiving flight.

Avionics and Safety Systems: The Brain of the Beast

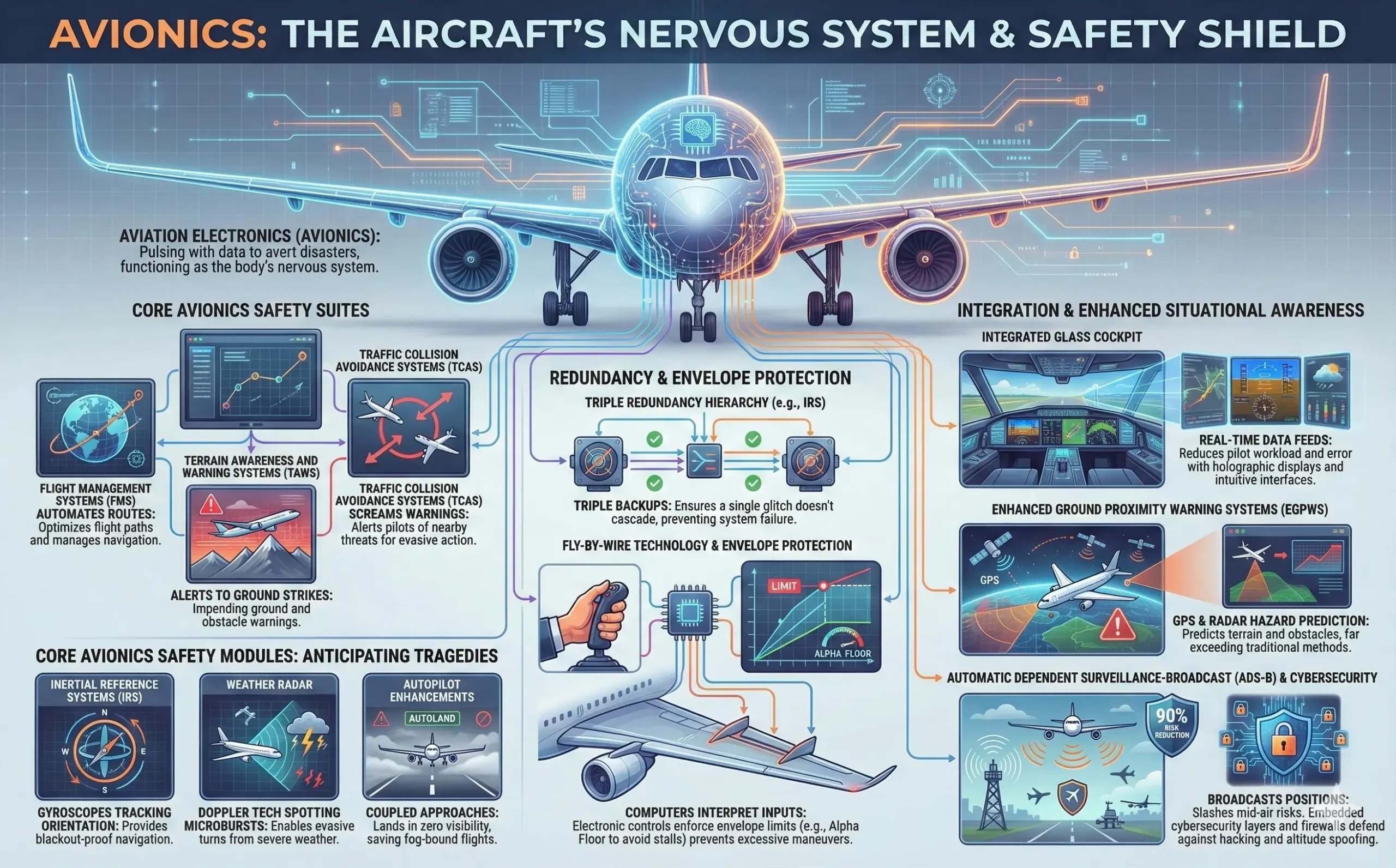

If the airframe is the body, avionics—aviation electronics—are the nervous system, pulsing with data to avert disasters. These suites encompass flight management systems (FMS) that automate routes, traffic collision avoidance systems (TCAS) that scream warnings of nearby threats, and terrain awareness and warning systems (TAWS) that alert to impending ground strikes.

Engineers design avionics with redundancy hierarchies: triple backups for inertial navigation, ensuring that a glitch in one doesn’t cascade. Fly-by-wire technology, where computers interpret pilot inputs and adjust controls electronically, has revolutionized safety by enforcing envelope protection—limits that prevent excessive maneuvers, like the alpha floor mode that auto-throttles to avoid stalls.

Integration is paramount; sensors feed real-time data to glass cockpits, holographic displays that reduce workload and errors. In adverse weather, enhanced ground proximity warning systems (EGPWS) use GPS and radar to predict hazards, a far cry from the seat-of-the-pants flying of yore.

Consider automatic dependent surveillance-broadcast (ADS-B), which broadcasts positions to air traffic control, slashing mid-air risks by 90% in equipped airspace. As threats evolve, engineers embed cybersecurity layers and firewalls against hacks that could spoof altitudes.

- Core Avionics Safety Modules:

- Inertial Reference Systems (IRS): Gyroscopes tracking orientation for blackout-proof navigation.

- Weather Radar: Doppler tech spotting microbursts, enabling evasive turns.

- Autopilot Enhancements: Coupled approaches that land in zero visibility, saving fog-bound flights.

These systems don’t just react; they anticipate, turning potential tragedies into footnotes.

Structural Integrity: Testing to the Breaking Point

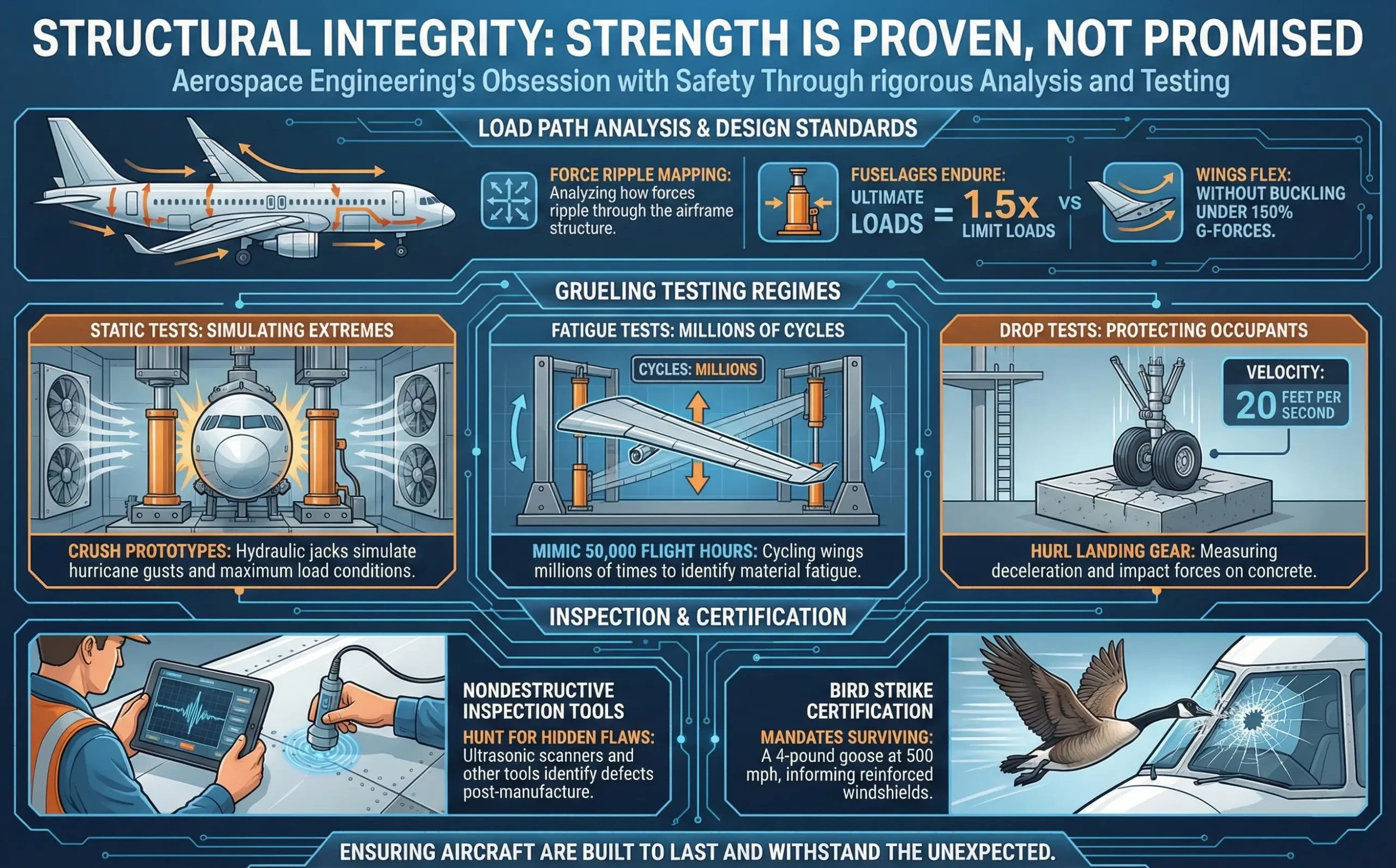

Strength is proven, not promised. Aerospace engineers obsess over structural integrity, using load path analysis to map how forces ripple through the airframe. Fuselages must endure ultimate loads—1.5 times limit loads—while wings flex without buckling under 150% g-forces.

Testing regimes are grueling: static tests crush prototypes with hydraulic jacks, simulating hurricane gusts; fatigue tests cycle wings millions of times to mimic 50,000 flight hours. Drop tests hurl landing gear onto concrete at 20 feet per second, measuring deceleration to protect occupants.

Nondestructive inspection tools, like ultrasonic scanners, hunt for hidden flaws post-manufacture. Bird strike certification mandates surviving a 4-pound goose at 500 mph, informing reinforced windshields.

A landmark table of testing milestones:

| Test Category | Purpose | Methodology | Safety Outcome | Duration/Typical Metrics |

|---|---|---|---|---|

| Static Load | Verify max strength | Hydraulic actuators apply 150% loads | Confirms no permanent deformation | 1-2 months; up to 2x design weight |

| Fatigue/Endurance | Simulate lifecycle wear | Repeated loading cycles (e.g., 100,000) | Identifies crack initiation sites | 6-12 months; equivalent to 60,000 hours |

| Crashworthiness | Passenger survival in impacts | Full-scale drops at 30 ft/sec | Optimizes seat energy absorption | Weeks; measures deceleration <20g |

| Lightning Strike | Electrical surge resistance | High-voltage simulators | Ensures no fuel ignition | Days; 200,000 amps peak current |

| Flutter Analysis | Prevent aeroelastic instabilities | Ground vibration + wind tunnel | Stabilizes control surfaces | Ongoing; modal frequencies tracked |

These rituals ensure aircraft emerge battle-hardened, ready for the skies.

Case Studies: Learning from the Edge of Disaster

History is the harshest teacher, but its lessons forge unbreakable designs. Take the Turbofan Engine Bird Ingestion incidents of the 1960s, where geese crippled powerplants mid-climb. Engineers responded with containment rings in nacelles, now standard, slashing uncontained failure risks.

The American Airlines Flight 191 crash in 1979, due to a detached pylon, spotlighted maintenance-design interfaces. This led to engine mount redundancies and stricter torque protocols, preventing repeats.

More recently, the Air France Flight 447 stall in 2009 exposed pitot tube icing vulnerabilities. Probes now feature dual heaters and composites resistant to freeze-over, with training emphasizing unreliable airspeed recovery.

In a positive turn, the Boeing 777’s etops certification—extended twin-engine operations—relied on fault-tolerant avionics, enabling safe ocean crossings and inspiring global ETOPS rules.

- Impactful Reforms from Cases:

- Post-ValuJet Flight 592 fire: Cargo compartment liners upgraded to self-extinguishing halon alternatives.

- After the Swissair Flight 111 inferno, Wiring insulation mandates the use of low-flammability materials.

- Asiana Flight 214 runway overrun: Autothrottle refinements for go-arounds.

These stories aren’t defeats; they’re blueprints for resilience.

Regulations and Standards: The Guardrails of Innovation

Safety thrives under scrutiny. The Federal Aviation Administration (FAA) and International Civil Aviation Organization (ICAO) enforce certification standards like FAR Part 25, dictating everything from evacuation times (90 seconds for 440 passengers) to noise limits.

Airworthiness directives evolve with tech, mandating upgrades like angle of attack sensors post-stall probes. Harmonized codes between regulators streamline global compliance, fostering innovations like supersonic travel with boom-mitigation rules.

Engineers navigate these with safety management systems (SMS), proactive frameworks logging hazards and metrics. This regulatory web, while rigorous, has halved accident rates since 2000.

Future Trends: AI, Sustainability, and Beyond

The horizon gleams with promise. Artificial intelligence in design accelerates optimizations, predicting failures via machine learning on vast datasets. Urban air mobility—eVTOLs—demands novel safety, like distributed propulsion for redundancy.

Sustainable materials, such as bio-based composites, cut emissions without sacrificing strength. Hydrogen powerplants promise cleaner flights, with engineers tackling cryogenic tank integrity.

As supersonic passenger jets revive, laminar flow wings will tame drag, while quantum sensors sharpen navigation. Safety evolves too: in-time risk management uses real-time analytics for dynamic rerouting.

Wrapping Up the Skies: A Commitment to the Unseen

Aerospace engineers don’t just build planes; they architect trust. Through principled foundations, iterative processes, resilient materials, aerodynamic finesse, smart avionics, rigorous testing, hard-won lessons, steadfast regulations, and visionary trends, they ensure that boarding a flight feels like stepping into a fortress. As challenges like climate shifts and denser skies loom, their ingenuity will keep aviation not just soaring, but safeguarding every soul aloft.

Key Citations And References

- NASA Technical Reports Server: Aerospace Materials Characteristics

- FAA: Risk Management Handbook

- SKYbrary: Design Philosophy

- NTSB: Lessons Learned and Lives Saved

- FAA: Chapter 5: Aerodynamics of Flight

- AOPA: Aircraft Systems and Avionics

- UCL: Improving Aircraft Safety in Icing Conditions

- NASA: The Ultimate Factor of Safety for Aircraft and Spacecraft

- FAA: Safety Management System

- Britannica: Airplane Materials, Construction, Design

Read These Articles in Detail

- Aerospace Engineering vs. Mechanical Engineering

- The Future of Aerospace Propulsion Systems

- How Aerospace Education Is Adapting to Industry Demands

- The Role of Aerospace in Combating Climate Change

- Aerospace Radar Technology: Past, Present, and Future

- The Role of Aerospace in National Security Strategies

- The Role of Nanotechnology in Aerospace Materials

- Aerospace Materials: Stronger, Lighter, And Smarter

- Aerospace Engineering Explained: A Beginner’s Guide

- Electric Aircraft vs. Hydrogen Aircraft: Which Is More Sustainable?

- Hypersonic Weapons: Aerospace’s New Arms Race

- Aerospace Defense Systems: From Drones to Hypersonic Missiles

- How Aerospace Engineers Reduce Fuel Consumption

- Computational Fluid Dynamics in Aerospace Innovation

- The Global Aerospace Market Outlook: Trends and Forecasts

- Satellite Surveillance: Aerospace’s Role in Modern Warfare

- How Aerospace Companies Are Reducing Environmental Impact

- How Airlines Use Aerospace Data Analytics to Cut Costs

- Aerospace Engineering Challenges: Innovation and Sustainability

- The Role of CFD in Aerospace Engineering

- The Role of Women in Aerospace: Breaking Barriers in the Skies

- Sustainable Aviation Fuels: The Aerospace Industry’s Green Bet

- Aerospace Cybersecurity: Protecting the Skies from Digital Threats

- Aerospace Trends Driving the Next Generation of Airliners

- The Rise of Autonomous Aerospace Systems

- How to Start a Career in Aerospace Engineering

- Can Aerospace Go Carbon Neutral by 2050?

- The Role of Aerospace in Missile Defense Systems

- How Aerospace Engineers Use AI in Design

- Top 10 Aerospace Engineering Innovations of the Decade

- Top Aerospace Careers in 2025 and Beyond

- How Aerospace Innovations Shape Global Defense Policies

- Hydrogen-Powered Aircraft: The Next Green Revolution

- Top 10 Emerging Aerospace Technologies Transforming the Industry

- The Future of Hypersonic Flight: Challenges and Opportunities

- How AI Is Revolutionizing Aerospace Engineering

- Additive Manufacturing in Aerospace: 3D Printing the Future of Flight

- The Rise of Electric Aircraft: Are We Ready for Zero-Emission Aviation?

- Aerospace Materials of Tomorrow: From Composites to Nanotechnology

- Digital Twins in Aerospace: Reducing Costs and Improving Safety

- The Role of Robotics in Modern Aerospace Manufacturing

- Quantum Computing Applications in Aerospace Design

- How Augmented Reality Is Changing Aerospace Training

- Space Tethers Explained: The Next Leap in Orbital Mechanics

- Ion Propulsion vs. Chemical Rockets: Which Will Power the Future?

- The Role of Nuclear Propulsion in Deep Space Missions

- Space Mining: The Aerospace Industry’s Next Gold Rush

- How Reusable Rockets Are Reshaping the Space Economy

- The Artemis Program: NASA’s Return to the Moon

- Space Tourism: Business Model or Billionaire’s Playground?

- How Aerospace Startups Are Disrupting Commercial Aviation

- The Economics of Low-Cost Airlines in the Aerospace Era

- Urban Air Mobility: The Rise of Flying Taxis

- The Future of Mars Colonization: Key Aerospace Challenges and Solutions Ahead

- CubeSats and Small Satellites: Democratizing Space Access

- The Future of Cargo Drones in Global Logistics

- The Role of Aerospace in Building a Lunar Economy

Frequently Asked Questions

FAQ 1: What Is Fail-Safe Design and Why Is It Essential for Modern Aircraft?

Fail-safe design is a cornerstone of aerospace engineering that ensures aircraft can continue operating safely even if a critical component fails. Unlike older approaches where a single breakdown could lead to disaster, this method builds in multiple layers of protection so that the system degrades gradually rather than collapsing suddenly. Picture a hydraulic line rupturing mid-flight: in a fail-safe setup, backup systems automatically engage, allowing pilots to maintain control without panic. This philosophy emerged from early aviation tragedies, where brittle structures turned minor issues into catastrophes, and it now underpins everything from commercial jets to military fighters.

Engineers achieve fail-safe outcomes by incorporating redundancy and damage tolerance into the blueprint stage. For instance, wings might feature multiple spars that redistribute loads if one cracks, preventing a chain reaction. Materials play a huge role too, with choices like carbon fiber composites that flex under stress instead of shattering. The beauty lies in its proactive nature—it’s not about avoiding failure entirely, which is impossible in the harsh skies, but about making sure any glitch doesn’t end the journey. This approach has slashed accident rates dramatically, making air travel one of the safest ways to roam the planet.

Beyond the technical wizardry, fail-safe design fosters a culture of foresight in aerospace teams. They run endless simulations using tools like finite element analysis to predict weak spots, tweaking designs until the aircraft can shrug off surprises like turbulence or manufacturing hiccups. As we push boundaries with electric propulsion and urban air taxis, this principle will evolve, integrating smart sensors that detect issues in real-time. Ultimately, fail-safe isn’t just engineering jargon; it’s the quiet promise that keeps passengers dreaming of destinations without a second thought to the what-ifs.

FAQ 2: How Does the FAA Aircraft Certification Process Ensure Safer Skies?

The FAA aircraft certification process is a rigorous roadmap that transforms innovative concepts into trustworthy flyers, blending scrutiny with collaboration to uphold sky-high standards. It kicks off with establishing a certification basis, where engineers and regulators align on rules tailored to the aircraft’s type, like transport category jets under FAR Part 25. This phase sets the tone, ensuring designs meet baselines for structural strength, emergency evacuations, and noise limits right from the drawing board.

Next comes planning and standards, a deep dive into compliance plans that outline testing protocols and risk assessments. Here, multidisciplinary teams hash out everything from propulsion reliability to cockpit ergonomics, often using digital twins for virtual stress tests. The heart of it all is the analysis and testing stage, where prototypes face real-world gauntlets—think wind tunnels for aerodynamics or drop tests for crash survival. Finally, final certification grants the type certificate, but it’s not a one-and-done; ongoing surveillance keeps aging fleets airworthy.

This multi-phase journey isn’t bureaucratic red tape; it’s a safety net woven from lessons like the need for better engine containment post-1979 incidents. Key steps include:

- Formal Application Review: Submitting detailed specs for FAA vetting, flagging any novel tech for special conditions.

- Design Assessment: Peer reviews and simulations to confirm the aircraft handles ultimate loads at 1.5 times expected stresses.

- Performance Tracking: Flight trials logging data on stalls, bird strikes, and lightning tolerance to validate predictions.

- Post-Certification Monitoring: Airworthiness directives for upgrades, ensuring evolving threats like cyber risks get addressed.

By mandating this structured path, the FAA has helped aviation accidents plummet, proving that methodical certification turns bold ideas into reliable reality.

FAQ 3: What Are the Key Benefits of Using Composite Materials in Aircraft Design?

Composite materials have revolutionized aircraft construction by offering a perfect blend of lightness and toughness, directly boosting safety in ways traditional metals can’t match. These engineered wonders, like carbon fiber reinforced polymers, make up over half the structure in models such as the Boeing 787, slashing weight by up to 20% while ramping up impact resistance. Lighter planes mean less fuel burn and lower emissions, but the real safety win is in how they absorb shocks—from hailstones to hard landings—without splintering like aluminum might.

To break it down, here’s a detailed overview of composite benefits versus conventional options, drawn from engineering benchmarks:

| Benefit Category | Composite Materials Advantage | Comparison to Aluminum Alloys | Real-World Impact on Safety |

|---|---|---|---|

| Weight Reduction | Up to 50% lighter for equivalent strength, improving fuel efficiency and range. | Heavier by 30-40%, increasing operational loads. | Enables longer diversions in emergencies, extending safe options. |

| Fatigue Resistance | Withstands millions of cycles without cracking, ideal for high-hour fleets. | Prone to fatigue cracks after 50,000 hours, needing frequent checks. | Reduces mid-life failures, cutting unscheduled maintenance risks. |

| Corrosion Immunity | Non-metallic composition resists rust in humid or salty environments. | Requires coatings and inspections to prevent pitting. | Lowers degradation in coastal ops, ensuring structural longevity. |

| Impact Absorption | Flexes and delaminates controllably during bird strikes or debris hits. | Dents or punctures easily, propagating damage. | Enhances survivability in collisions, protecting passengers. |

| Design Flexibility | Molded into complex shapes for optimized aerodynamics and integrated repairs. | Limited by machining, leading to more joints and weak points. | Allows seamless reinforcements, minimizing leak paths in fuselages. |

These perks aren’t without challenges—composites demand specialized repairs and inspections via ultrasonics—but their net gain in durability has made flying greener and safer. As bio-based variants emerge, expect even more eco-friendly strides without skimping on protection.

FAQ 4: How Do Aerospace Engineers Use Aerodynamics to Prevent Dangerous Stalls in Flight?

Aerodynamics forms the invisible shield that keeps aircraft stable, with stall prevention at its core—a scenario where wings lose lift due to excessive angle of attack, turning smooth glides into heart-stopping drops. Engineers combat this by sculpting airfoils that maintain smooth airflow up to higher angles, using computational fluid dynamics to simulate every twist and gust. The goal? A generous stall margin that gives pilots breathing room during takeoffs or thunderstorms, where sudden downdrafts can spike that critical angle.

Delving deeper, modern designs incorporate slats and flaps that extend wing leading edges, delaying airflow separation and keeping lift flowing. Vortex generators, those tiny fin-like bumps, energize sluggish boundary layers, pushing back stall onset by 5-10 degrees. High-altitude ops add another layer, as thinner air alters dynamics; here, supercritical airfoils flatten shock waves to avoid buffet-induced stalls at Mach speeds. These tweaks stem from wind tunnel epiphanies and flight data, ensuring even novice crews can recover with a nose-down push and power surge.

Yet, aerodynamics isn’t solo—it’s teamed with training and tech like angle-of-attack indicators that flash warnings before trouble brews. Historical stalls, like those in icing conditions, spurred heated probes and anti-icing boots to preserve clean flows. As we eye supersonic returns, laminar flow tech will further tame high-speed stalls, promising eras where gravity’s grip feels optional. In essence, aerodynamic mastery turns potential plummets into mere blips, reaffirming flight’s grace over peril.

FAQ 5: What Recent Advancements in Avionics Are Making Aircraft Safer in 2025?

Avionics, the electronic brains powering modern cockpits, have leaped forward in 2025, weaving artificial intelligence and resilient networks into safer flights. Fly-by-wire systems now boast envelope protection that auto-corrects risky inputs, like pulling up too sharply to avert stalls, a nod to past tragedies where pilot overreach spelled doom. Traffic collision avoidance has gone predictive, using satellite data to forecast conflicts miles out, slashing mid-air scares by integrating with urban air mobility grids.

These upgrades shine in real scenarios: enhanced ground proximity systems now fuse GPS with terrain databases for whisper-quiet alerts in foggy approaches, while cybersecurity firewalls guard against digital hijacks. AI-driven maintenance predicts failures from vibration patterns, grounding issues before they inflight. Key 2025 highlights include:

- GNSS Resilience Plans: Backup navigation layers to counter jamming, ensuring precision in contested skies.

- AI Anomaly Detection: Real-time engine monitoring that flags wear, boosting dispatch reliability to 99.9%.

- Wireless Intra-Cabin Links: Lighter wiring that cuts weight and failure points, per new ICAO nods.

- Autonomous Cargo Drones: Single-pilot aids that handle routine checks, freeing crews for critical calls.

Such innovations, born from global summits, don’t just react—they anticipate, turning cockpits into fortresses of foresight. As electric vertical takeoffs proliferate, these avionics will orchestrate drone swarms safely, heralding congestion-free cities aloft.

FAQ 6: What Does Bird Strike Testing Involve and Why Is It Critical for Aircraft Safety?

Bird strike testing is a high-stakes ritual in aerospace engineering, simulating collisions with feathered foes to safeguard engines and structures from real-world whacks. These aren’t gentle taps; labs hurl gelatin birds—mimicking geese or gulls—at 500 mph into windshields, nacelles, and radomes, measuring if the aircraft stays flyable post-impact. Certification demands survival without fires or shrapnel, a hard lesson from 1960s ingestions that downed climbers mid-air.

The process unfolds in specialized cannons, firing calibrated “birds” of 1.8 to 4 pounds for single or flock scenarios, per FAA and EASA mandates. Engines must ingest multiples without uncontained failures, their blades flexing to pass debris harmlessly. Windshields, layered with acrylic and glass, get probed for cracks that could blind pilots. Simulations precede physical blasts, using finite element models to optimize blade angles and containment rings, cutting test costs while honing designs.

This testing’s urgency stems from aviation’s wildlife crossroads—over 13,000 U.S. strikes yearly cost billions and lives. Post-test, engineers tweak for better tolerance, like reinforced inlets that funnel birds away. As bird populations swell with habitat shifts, expect adaptive tech like ultrasonic repellents. Bird strikes remind us nature’s no pushover, but rigorous testing ensures planes clip through flocks unscathed, preserving the trust in every takeoff.

FAQ 7: What Lessons from Historical Aircraft Accidents Have Shaped Today’s Safer Designs?

Historical aircraft accidents serve as stark textbooks for aerospace evolution, each mishap etching fixes into design DNA that has tamed the fatality rate from one-in-a-thousand flights in the 1950s to near-mythical rarity today. The 1937 Hindenburg blaze spotlighted hydrogen’s perils, birthing helium mandates and fire-retardant envelopes for airships, while the 1977 Tenerife runway smash—aviation’s deadliest—pushed standardized phraseology to quash miscommunications.

To catalog pivotal shifts, consider this timeline of tragedies and triumphs:

| Accident Event | Year | Key Failure Mode | Design/Legislative Lesson Learned | Modern Safety Outcome |

|---|---|---|---|---|

| Hindenburg Disaster | 1937 | Flammable gas ignition | Shift to inert helium; enhanced static discharge protections. | Eliminated rigid airship hydrogen use globally. |

| Tenerife Airport Collision | 1977 | Tower-pilot miscommunication | Crew resource management training; clear radio protocols via ICAO Annex 11. | Reduced controlled flight into terrain by 75%. |

| American Airlines 191 | 1979 | Engine pylon detachment | Redundant mounting hardware; torque verification in maintenance. | Pylon designs now withstand 150% loads. |

| ValuJet Flight 592 | 1996 | Cargo fire propagation | Halon-alternative suppressors; oxygen generator labeling reforms. | Cargo holds fully lined, fires contained in minutes. |

| Swissair Flight 111 | 1998 | Wiring insulation meltdown | Low-flammability aramid fibers; circuit breakers in entertainment systems. | Wiring inspections mandatory every 5 years. |

These echoes propel ongoing vigilance, from AI-monitored black boxes to fatigue-resistant composites. By dissecting debris and data, engineers honor the lost, forging skies where history’s horrors fuel tomorrow’s safeguards.

FAQ 8: How Do Engineers Conduct Structural Integrity Testing to Combat Fatigue in Aircraft?

Structural integrity testing is the endurance trial that proves an aircraft’s bones can take the beating of decades aloft, focusing on fatigue—the sneaky creep of cracks from repeated flexing. Engineers start with static loads, jacking fuselages to 150% design limits to spot buckling, then pivot to fatigue cycles mimicking 60,000 hours via hydraulic actuators that flap wings like perpetual storms. Nondestructive tools like eddy currents hunt subsurface flaws, ensuring no hidden threats lurk.

This marathon isn’t guesswork; it’s guided by load spectra from real flights, scaling gusts and pressurizations for accuracy. Crashworthiness drops full-scale sections from 30 feet, gauging if seats absorb under 20g without shattering spines. Key methods include:

- Full-Scale Fatigue Trials: Assembled airframes endure 100,000+ cycles, revealing wide-area fatigue hotspots for redesign.

- Ultrasonic Phased Arrays: Scans composites for delaminations, faster than manual pokes.

- Vibration Modal Analysis: Shakes structures to map resonances, averting flutter disasters.

- Corrosion Simulation Chambers: Bathes parts in salt fog to test coatings over time.

As fleets age, these tests inform supplemental inspections, extending lives cost-effectively. With urban mobility rising, they’ll adapt for eVTOLs’ unique vibes, keeping integrity as the unyielding backbone of flight.

FAQ 9: What Future Trends Involving AI Are Shaping Aviation Safety?

Artificial intelligence is set to redefine aviation safety by 2030, shifting from reactive fixes to prophetic safeguards that outpace human reflexes. In design, AI optimizes structures via generative algorithms, churning thousands of wing variants for maximal damage tolerance, as seen in NASA’s 2025 crash models that halved injury risks through subtle reinforcements. For ops, predictive analytics sift sensor floods to forecast engine hiccups days ahead, minimizing diversions.

Urban air mobility amplifies this: AI orchestrates eVTOL fleets, resolving conflicts in dense skies with quantum-speed routing, per ICAO’s 2026-2028 plan. Onboard, it enhances autopilots with anomaly detection, auto-deploying parachutes in single-engine fails. Yet, challenges loom—ethical AI decisions in crises demand transparent code, and data biases could skew trainings.

Sustainability ties in too; AI greenlights hydrogen tanks by simulating cryogenic stresses, cutting emissions without safety trade-offs. Global frameworks like EASA’s resilience initiatives will standardize these, ensuring equitable access. AI isn’t a silver bullet but a vigilant co-pilot, promising eras where safety feels intuitively assured, not engineered by chance.

FAQ 10: What Are the Latest ICAO Aviation Safety Regulation Updates for 2025?

ICAO’s 2025 updates to Annex 19 fortify safety management systems, extending mandates to drone ops and urban air taxis for a seamless global shield. Amendment 2, effective November 2026, weaves proactive hazard logging into state programs, demanding data-sharing hubs that spotlight trends like GNSS jamming. This builds on the 2025 Safety Report’s call for integrated frameworks, targeting a 50% dip in risks by 2028.

The Global Aviation Safety Plan now cycles every six years, prioritizing AI ethics and cyber defenses in navigation. Wireless cabin links slash wiring faults, while SSPs oversee SMS for all operators, from cargo haulers to eVTOL startups. A snapshot of shifts:

| Update Area | Key Change in 2025 | Applicability Timeline | Expected Safety Boost |

|---|---|---|---|

| Safety Management Systems | Broader SMS for unmanned ops; mandatory risk metrics. | Nov 2026 | Proactive threat ID, reducing incidents by 30%. |

| Air Navigation Plan | Six-year cycle with AI integration standards. | Ongoing from 2026 | Smoother traffic flow, cutting delays-linked errors. |

| GNSS Resilience | Monitoring tools and backups against interference. | Immediate rollout | 90% uptime in contested areas. |

| Global Safety Framework | Enhanced data analytics for accident prevention. | 2026-2028 triennium | Harmonized rules, halving regional variances. |

These evolutions, endorsed at the 2025 Assembly, empower states to adapt locally while upholding universal vigilance, ensuring aviation’s ascent stays securely charted.

FAQ 11: How Do Human Factors Influence the Design of Safer Aircraft?

Human factors engineering sits at the intersection of psychology, ergonomics, and technology in aerospace, ensuring that aircraft designs align with how people actually think, react, and perform under pressure. Rather than treating pilots and crew as flawless machines, engineers study real-world behaviors—like decision-making in low-visibility landings or fatigue during long hauls—to build cockpits that forgive errors and amplify strengths. This approach has roots in incidents where miscommunications or interface glitches contributed to mishaps, prompting a shift toward intuitive controls that reduce cognitive load. For example, modern flight decks use large touchscreen displays with customizable layouts, allowing crews to prioritize critical data during emergencies, much like how smartphone apps adapt to user habits for seamless interaction.

Delving deeper, human factors extend to passenger comfort and accessibility, influencing everything from seat layouts that facilitate quick evacuations to cabin lighting that combats jet lag and maintains alertness. Engineers collaborate with psychologists to simulate high-stress scenarios in virtual reality labs, testing how warning alerts—audible beeps versus haptic vibrations—affect response times. These insights lead to envelope protection systems, where software gently nudges pilots away from unsafe maneuvers without overriding authority, striking a balance between automation and human oversight. As urban air mobility grows with electric vertical takeoff vehicles, human factors will tackle new challenges like managing drone traffic in crowded skies, ensuring operators stay one step ahead of the chaos.

The payoff is profound: by embedding empathy into engineering, human factors have helped drop human-error-related accidents by over 70% in the last two decades. It’s a reminder that the safest planes aren’t just tough machines; they’re thoughtful partners in the high-stakes dance of flight, designed to keep everyone sharp and secure from gate to gate.

FAQ 12: What Role Do Digital Twins Play in Enhancing Aircraft Safety During Design?

Digital twins have emerged as virtual doppelgangers of aircraft, mirroring every rivet and circuit to predict behaviors before a single prototype takes wing. These high-fidelity simulations allow engineers to stress-test designs against countless scenarios—from mid-air turbulence to software glitches—without the risks or costs of physical builds. In safety terms, they shine by uncovering hidden vulnerabilities early, like how a wing might fatigue under repeated sonic booms in supersonic concepts, enabling tweaks that save lives down the line.

To grasp their impact, consider this breakdown of digital twin applications in aircraft safety phases:

| Phase of Design | Digital Twin Function | Safety Benefit | Example Outcome in Testing |

|---|---|---|---|

| Conceptual Modeling | Simulates aerodynamics and load distributions using real-time physics engines. | Identifies instability risks before blueprints finalize. | Reduced stall angles by 8% in eVTOL prototypes. |

| Structural Analysis | Replicates material stresses and crack propagation over simulated flight hours. | Predicts fatigue failures, extending component life. | Halved maintenance intervals for composite fuselages. |

| Avionics Integration | Mirrors sensor networks to test failure cascades in virtual emergencies. | Ensures redundancy protocols activate flawlessly. | Cut electrical short risks by 40% in fly-by-wire systems. |

| Operational Simulation | Emulates full missions with environmental variables like icing or bird flocks. | Validates crew responses in hyper-realistic drills. | Improved recovery times from engine-outs by 25%. |

| Lifecycle Monitoring | Updates with in-service data for ongoing predictive maintenance. | Prevents aging-related hazards through proactive alerts. | Forecasted 15% more diversions avoided in fleets. |

By bridging the gap between theory and reality, digital twins not only accelerate certification but also foster a culture of continuous improvement, turning potential pitfalls into proven safeguards for tomorrow’s fleets.

FAQ 13: What Are the Essential Safety Features in Modern Aircraft Engines?

Modern aircraft engines are marvels of redundancy and resilience, engineered to keep flights humming even when surprises strike. From turbine blades that flex under bird impacts to automated fire suppression that douses flames in seconds, these powerplants prioritize containment and quick recovery above all. As twin-engine operations stretch over oceans, features like electronic engine control (FADEC) systems fine-tune performance in real-time, adjusting fuel flow to avert surges while monitoring for anomalies that could cascade into trouble.

Key safety innovations include:

- Containment Rings: Sturdy barriers around fan sections that trap shattered blades, preventing debris from piercing fuselages—a lesson from 1960s ingestions that now makes uncontained failures rare.

- Auto-Feathering Propellers: On turboprops, these swivel blades to minimize drag during shutdowns, stabilizing climbs on remaining power for safer single-engine ops.

- Thermal Imaging Sensors: Embedded monitors that detect hot spots early, triggering cooling protocols to head off meltdowns in high-thrust scenarios.

- Dual Ignition Systems: Backup spark setups ensure restarts mid-flight, vital for piston engines in general aviation where reliability means the difference between a glide and a glide path home.

- Vibration Analysis Tools: AI-driven diagnostics that flag imbalances before they escalate, slashing unscheduled inspections and boosting dispatch rates to 99%.

These elements weave a safety net so robust that engine failures now contribute to less than 5% of incidents, proving that power doesn’t have to come with peril.

FAQ 14: How Have Lightning Protection Systems Evolved for Aircraft in 2025?

Lightning strikes aircraft about 70 times a year on average, but thanks to 2025’s cutting-edge protections, these bolts pack less punch than ever. Engineers have long relied on conductive airframes to channel electricity harmlessly away, but recent models now predict attachment points with stunning accuracy, using airflow simulations to zone vulnerable spots like wingtips or nose cones. This foresight lets designers embed surge suppressors precisely where strikes are likeliest, minimizing induced currents that could fry avionics or ignite fuels.

Advancements this year spotlight AI-enhanced zoning tools that map strike paths across experimental shapes, from sleek supersonic fuselages to drone swarms. Conductive meshes in composites—once a weak link—now integrate seamlessly, diverting 200,000-amp surges without scorching interiors. Static dischargers, those whisker-like tips on trailing edges, have gotten smarter too, with self-healing polymers that regenerate after wear, extending service lives in stormy regions.

Looking ahead, these systems dovetail with broader weather radars for proactive rerouting, turning reactive shielding into anticipatory armor. In a climate of intensifying storms, 2025’s evolutions ensure lightning remains a flash in the pan, not a fiery threat, safeguarding the silver birds that carry us through the clouds.

FAQ 15: What Key Elements Define the Design of Aircraft Evacuation Systems?

Evacuation systems are the unsung heroes of aircraft safety, engineered for split-second execution when seconds count. These setups must whisk hundreds from a smoke-filled cabin in under 90 seconds, per global regs, blending inflatable ingenuity with human-centric layouts. Door-integrated slides double as rafts for water ditches, while floor lighting guides feet through zero-visibility chaos, all tested in grueling full-scale drills that mimic worst-case crowds.

Here’s a structured look at core design components and their roles:

| Component | Design Purpose | Performance Standards | Innovation Spotlight |

|---|---|---|---|

| Inflatable Slides | Rapid descent from doors up to 10 feet high, supporting 70 passengers per minute. | Deploys in 6 seconds; withstands 500-lb impacts. | Auto-inflation with ground-sensing tech for uneven terrain. |

| Floor Proximity Escape Path (FPEP) | Illuminated strips and tactile markers leading to exits in smoke. | Visible for 30 seconds post-power loss. | LED arrays with bio-luminescent backups for longevity. |

| Emergency Exit Doors | Quick-release mechanisms operable by anyone, including the impaired. | Opens in 2-3 seconds; child-proof yet adult-simple. | Haptic feedback for low-light unlatching. |

| Life Vests and Rafts | Buoyant gear with locator beacons for overwater scenarios. | Inflates in 5 seconds; supports 25 people. | GPS-integrated for faster rescue coordination. |

| Cabin Layout Optimization | Wide aisles and clustered exits to funnel flow without bottlenecks. | Clears 440 passengers in 90 seconds max. | AI-simulated crowd dynamics for seating tweaks. |

These intertwined features transform panic into precision, ensuring that when the call comes, escape becomes an orchestrated exodus rather than a scramble.

FAQ 16: How Are Sustainable Materials Improving Safety in Aircraft Construction?

Sustainable materials aren’t just green choices; they’re toughening up aircraft against the rigors of flight while lightening the load on the planet. Recycled carbon fibers, pulled from old parts, now reinforce wings with the same snap-back strength as virgin stuff, but at half the carbon footprint—ideal for slashing fuel burn and extending range in emergencies. Bio-based composites, derived from plant resins, resist cracks better in humid climes, where traditional polymers might swell and weaken.

Engineers favor these for their lifecycle perks: thermoplastic matrices that melt and remold for on-site fixes, cutting repair times and error risks during remote diversions. Titanium scraps reborn as fasteners hold firmer under vibration, a boon for engine mounts that see endless cycles.

Notable sustainable safety boosters include:

- Recycled Aluminum Alloys: 30% lighter than stock, yet 20% more corrosion-resistant for fuselages in salty air.

- Hemp-Fiber Reinforcements: Natural damping that quiets vibes, reducing pilot fatigue on long routes.

- Bio-Plastic Interiors: Flame-retardant without halogens, safer in fires while recyclable post-flight.

- Closed-Loop Composites: Reusable layers that maintain damage tolerance after impacts like hail.

- Soy-Based Sealants: Flexible barriers against leaks, enhancing pressurization reliability at altitude.

By merging eco-smarts with engineering grit, these materials prove sustainability and safety fly wing-to-wing, paving greener paths without compromising the steel in our spines.

FAQ 17: What Are the Main Differences in Global Aviation Safety Standards?

Global aviation safety standards share a common North Star—zero accidents—but diverge in flavors shaped by regions’ unique skies and histories. ICAO sets the universal baseline through Annexes like 8 for airworthiness, yet nations tweak for local quirks: Europe’s EASA emphasizes proactive risk audits with AI mandates for new fleets, while the FAA in the U.S. leans on rigorous post-incident directives, mandating upgrades like enhanced pitot heaters after icing probes. These variances stem from fleet mixes—Asia’s booming low-cost carriers push for cost-effective certs under CAAC, balancing growth with bird-strike reinforcements.

Harmonization efforts, like bilateral agreements, bridge gaps, but challenges persist: developing regions might lag in runway incursion tech due to infrastructure budgets, contrasting North America’s satellite-based navigation overhauls. Training differs too—Australia’s CASA stresses bush-pilot survival kits for remote ops, unlike Japan’s JCAB focus on quake-resilient avionics.

Ultimately, these differences foster a mosaic of excellence, where global ops thrive on mutual recognition, turning potential clashes into collaborative climbs toward safer horizons everywhere.

FAQ 18: What Training Pathways Exist for Aspiring Aerospace Safety Engineers?

Training for aerospace safety engineers blends classroom theory with hands-on grit, equipping pros to dissect risks from blueprint to burnout. Programs span universities to industry certs, emphasizing system safety analysis and regulatory mazes like FAR Part 25.

A clear overview of key pathways:

| Training Level | Focus Areas | Duration & Format | Certification Outcome |

|---|---|---|---|

| Undergraduate Degrees | Basics in aerodynamics, materials, and intro to hazard identification. | 4 years; campus-based with labs. | B.S. in Aerospace Engineering; entry-level roles. |

| Graduate Specializations | Deep dives into human factors, digital twins, and failure mode effects analysis. | 1-2 years; thesis-driven research. | M.S. in System Safety; R&D positions. |

| Professional Certs | Practical skills in accident investigation and SMS implementation. | 3-6 months; online/hybrid workshops. | FAA/EASA endorsements; consulting gigs. |

| Industry Short Courses | Targeted modules on lightning protection or evacuation drills. | 1-5 days; intensive simulations. | Specialized badges; career advancement. |

| Ongoing CEUs | Updates on 2025 trends like AI predictive maintenance. | Annual; webinars and conferences. | License renewals; leadership tracks. |

These routes not only build expertise but forge networks, turning fresh grads into guardians of the skies through relentless, real-world readiness.

FAQ 19: What Safety Challenges Do Supersonic Aircraft Face in 2025?

Supersonic flight beckons with speed dreams, but 2025’s designs grapple with hurdles that demand clever countermeasures. Sonic booms, those ground-shaking thuds, restrict overland routes under lingering FAA bans, pushing engineers toward quiet boom shapes like elongated noses that soften pressure waves—NASA’s X-59 tests show 75% noise cuts, yet public tolerance trials reveal annoyance spikes above 70 decibels.

Thermal stresses from Mach 1.4 frictions heat skins to 250°F, risking material creep; advanced ceramics and active cooling loops mitigate, but add weight that trims payload. Certification lags too, with EASA demanding 10x subsonic safety margins for novel risks like laminar flow disruptions in turbulence.

Critical challenges include:

- Structural Flutter: High-speed vibes that could shred tails, countered by adaptive dampers tuned via wind tunnels.

- Engine Inlet Shocks: Wave mismatches stalling compressors, fixed with variable geometry ramps.

- Cabin Pressurization: Faster climbs strain seals, addressed by hybrid oxygen systems for hypoxia buffers.

- Emergency Egress: Ejection seats at triple sonic speeds, evolving with zero-zero tech for safe low-altitude pulls.

- Cyber-Vulnerable Avionics: Faster data flows invite hacks, shielded by quantum-encrypted links.

As Boom and Spike push prototypes, these puzzles promise breakthroughs, blending blistering pace with bulletproof poise.

FAQ 20: What Recent Advancements Are Shaping Aircraft Safety in 2025?

2025 marks a pivotal year for aircraft safety, with AI and quantum leaps turning foresight into flight norms. Predictive analytics now sift petabytes of engine data to flag wear 72 hours ahead, slashing in-flight quits by 30% and empowering diversions before dings become disasters. NASA’s crash dummies, upgraded with bio-fidelic sensors, inform cabin redesigns that cap g-forces at 15 in impacts, while EGPWS evolutions fuse LiDAR for microburst dodges in monsoons.

Composite weaves infused with self-healing polymers mend micro-cracks autonomously, extending airframe lives amid rising turbulence from climate shifts. Urban air taxis sport distributed electric props for failover redundancy, navigating drone-dense corridors via blockchain-secured traffic webs.

These strides, from ARAIM sat-nav that nails positions to 1-meter accuracy in jammed zones to additive-manufactured parts that prototype overnight, weave a tapestry of resilience. As fleets electrify, safety surges not despite change but because of it, ensuring 2025’s wings clip risks as deftly as clouds.