Key Insights on AI’s Role in Aerospace Engineering

- Rapid Innovation Through Generative Design: AI algorithms generate thousands of design options, optimizing for weight, strength, and aerodynamics, cutting development time from months to hours.

- Faster Simulations and Predictions: Tools like surrogate models reduce computational fluid dynamics runs from hours to milliseconds, enabling real-time iterations.

- Real-World Impact: Companies like Airbus and NASA report up to 10,000-fold speed increases in predictions, leading to lighter, more efficient aircraft.

- Challenges Ahead: While the benefits are clear, issues such as data security and model explainability require careful human oversight to ensure safety.

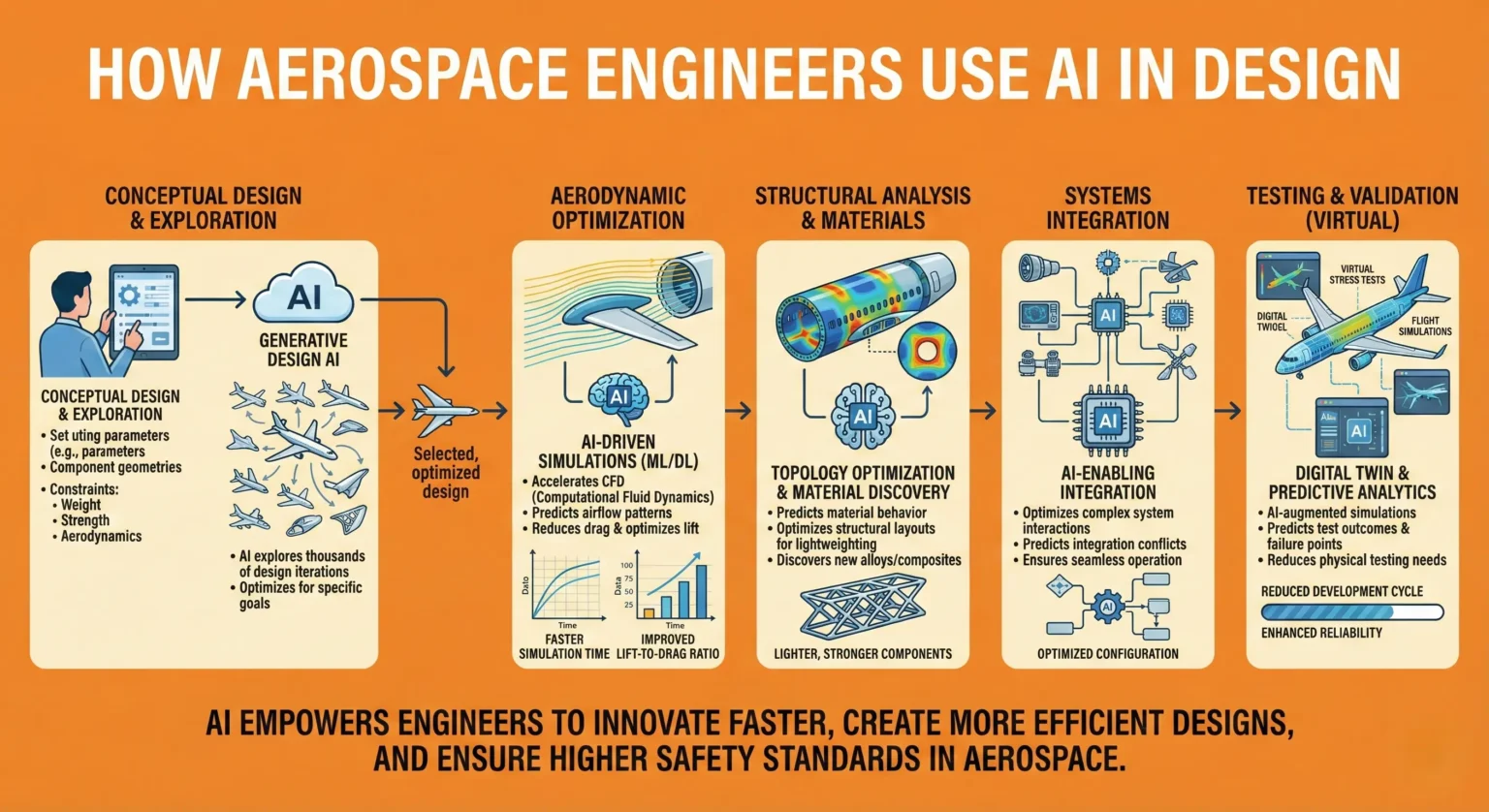

Overview of AI Integration

Aerospace design traditionally relies on manual iterations and physical prototypes, but artificial intelligence (AI) is transforming this by automating complex tasks. Engineers now use AI to explore vast design spaces, predict performance, and optimize structures, making aircraft and spacecraft safer and more efficient.

Core Applications

- Generative Design: AI creates novel geometries based on constraints.

- Optimization Techniques: Machine learning refines aerodynamics and materials.

- Simulation Acceleration: High-fidelity models paired with AI for quick validations.

Why It Matters

This shift not only speeds up innovation but also reduces costs, with potential savings in fuel efficiency translating to millions annually.

Table of Contents

Exploring the Transformative Power of AI in Aerospace Design

Aerospace engineering has always pushed the boundaries of human ingenuity, from the Wright brothers’ first flight to today’s reusable rockets piercing the atmosphere. Yet, in an era where every gram counts and safety margins are razor-thin, traditional design methods—relying on exhaustive manual calculations and wind tunnel tests—often fall short in speed and scope. Enter artificial intelligence (AI), a game-changer that’s redefining how engineers dream up the next generation of wings, fuselages, and propulsion systems. By harnessing machine learning algorithms, neural networks, and generative models, AI doesn’t just assist; it amplifies creativity, turning abstract concepts into feasible blueprints with unprecedented efficiency.

This article delves deep into the multifaceted ways aerospace engineers wield AI in design, drawing on cutting-edge applications, real-world examples, and forward-looking trends to paint a comprehensive picture of this evolving landscape.

Why AI Fits Perfectly in Aerospace Design

Aerospace design grapples with intricate trade-offs: balancing fuel efficiency against payload capacity, structural integrity against weight, and performance against cost. These challenges demand processing massive datasets—from wind flow simulations to material stress analyses—far beyond human computation alone. AI steps in as a tireless collaborator, learning from historical data and physics-based models to predict outcomes and suggest innovations.

Consider the sheer scale: A single aircraft design cycle can involve millions of variables, iterated over years. AI compresses this by automating repetitive tasks, allowing engineers to focus on strategic decisions. For instance, machine learning (ML) models trained on past projects can forecast how a wing’s curvature affects drag, enabling tweaks in real time rather than after weeks of prototyping. This isn’t sci-fi; it’s the new normal, driven by advancements in computational power and accessible algorithms.

Moreover, AI’s adaptability shines in handling uncertainty—critical in aerospace, where variables like atmospheric turbulence or material fatigue are unpredictable. By integrating probabilistic methods, AI quantifies risks early, fostering designs that are not just innovative but resilient. As engineers increasingly collaborate with these digital tools, the field is witnessing a paradigm shift from trial-and-error to data-driven precision.

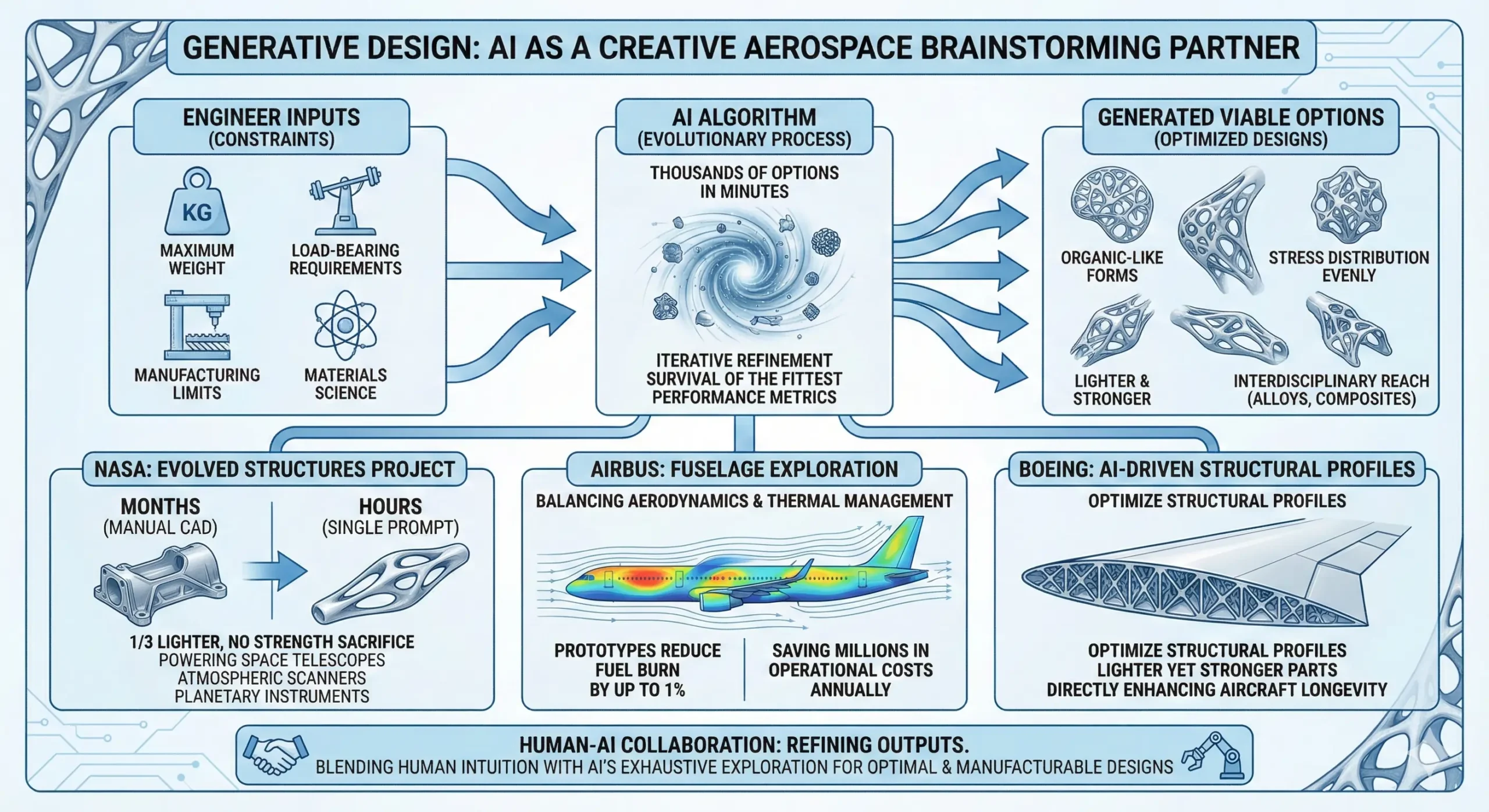

Generative Design: Unleashing Creativity with Algorithms

One of the most exhilarating applications of AI in aerospace is generative design, where algorithms act like a brainstorming partner on steroids. Engineers input constraints—such as maximum weight, load-bearing requirements, and manufacturing limits—and AI generates a plethora of viable options, often thousands, in minutes. This process mimics natural evolution, iteratively refining shapes through simulated “survival of the fittest” based on performance metrics.

Take NASA’s Evolved Structures project as a prime example. Here, generative AI slashed hardware design time from months of manual computer-aided design (CAD) work by an entire team to mere hours for a single prompt. The result? Structures one-third lighter without sacrificing strength, now powering space telescopes, atmospheric scanners, and planetary instruments. These organic-like forms, resembling bone lattices, distribute stress more evenly, a feat human designers might overlook amid conventional straight-line thinking.

Beyond NASA, major players are embedding generative design into workflows. Airbus engineers use it to explore fuselage components, balancing aerodynamics with thermal management. The outcome: Prototypes that reduce fuel burn by up to 1%, a small tweak with massive implications—saving airlines millions in operational costs annually. Boeing, too, patents AI-driven tools that optimize structural profiles, yielding parts that are lighter yet stronger, directly enhancing aircraft longevity.

What makes generative design so potent is its interdisciplinary reach. It doesn’t stop at shapes; it incorporates materials science, suggesting alloys or composites that withstand extreme conditions. Engineers refine these outputs, blending human intuition with AI’s exhaustive exploration, ensuring designs are not only optimal but manufacturable.

To illustrate the breadth, here’s a table comparing traditional versus AI-enhanced generative design processes:

| Aspect | Traditional Design Approach | AI-Enhanced Generative Design Approach |

|---|---|---|

| Time to Generate Options | Weeks to months, involving multiple manual iterations | Hours to days, with automated exploration of 1,000+ variants |

| Number of Design Variants | Limited to 10-50, constrained by human bandwidth | Thousands to millions, covering diverse geometries |

| Optimization Focus | Primarily on single objectives (e.g., weight) | Multi-objective (weight, strength, aerodynamics, cost) |

| Human Involvement | High; engineers draft and refine manually | Low initial; focused on validation and final tweaks |

| Example Outcome | Standard wing shapes based on historical precedents | Lattice-inspired structures reducing weight by 30% |

| Cost Implications | Higher due to prolonged prototyping | Lower, with 20-50% reduction in R&D expenses |

This table highlights how AI democratizes innovation, making sophisticated designs accessible to even smaller teams.

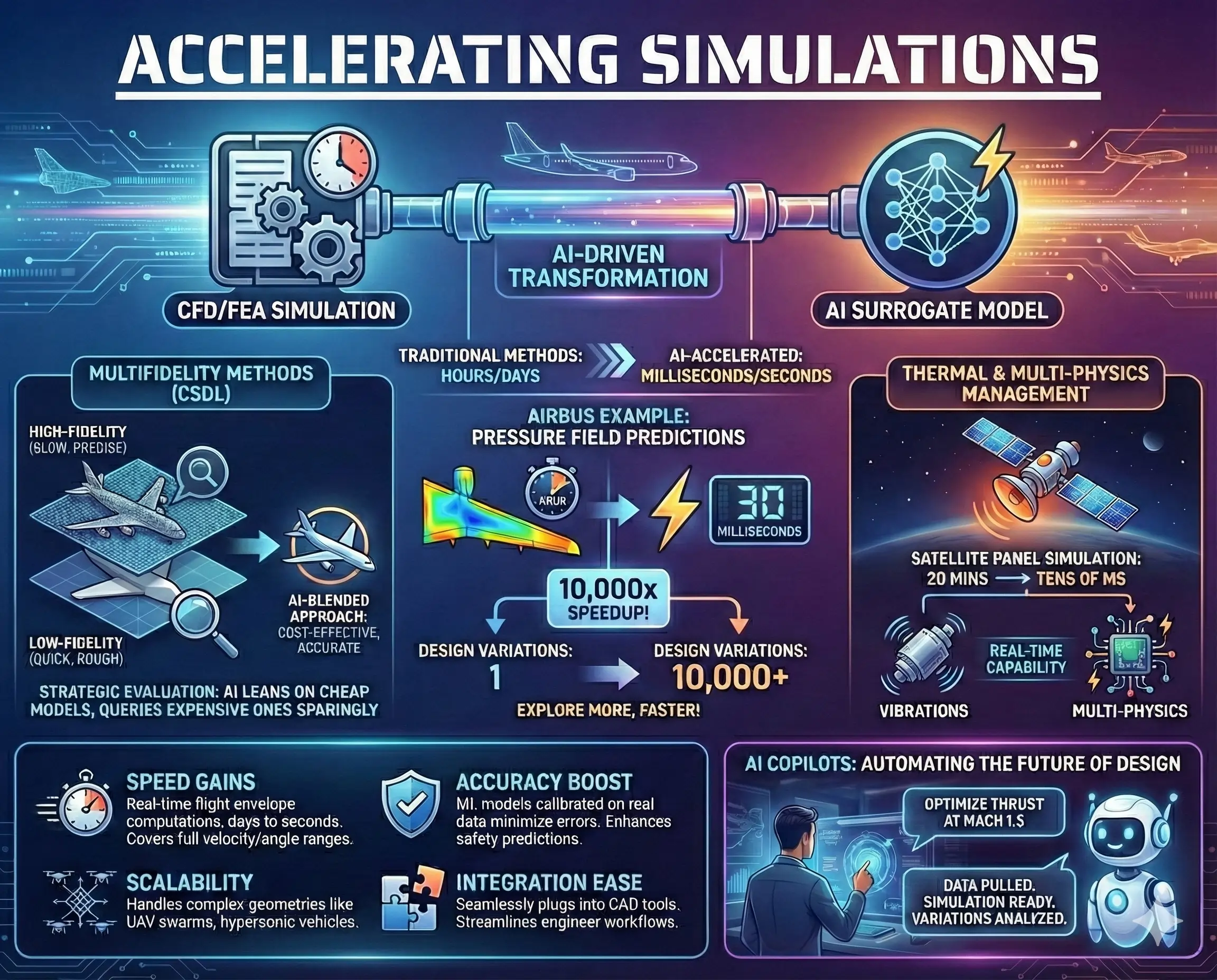

Accelerating Simulations: From Hours to Milliseconds

Simulations form the backbone of aerospace design, validating concepts before a single rivet is placed. Traditional computational fluid dynamics (CFD) and finite element analysis (FEA), while accurate, are computationally voracious—running a single aerodynamic test might take hours on supercomputers. AI revolutionizes this by creating surrogate models, neural networks that learn from high-fidelity simulations to predict results instantaneously.

Airbus’s collaboration exemplifies this leap. Using AI platforms, they slashed pressure field predictions from one hour to 30 milliseconds—a staggering 10,000-fold speedup. This allows engineers to test 10,000 more design variations, uncovering subtle improvements in lift or drag that traditional methods might miss. The platform handles not just fluids but structures and electromagnetics, enabling holistic design explorations without massive hardware upgrades.

In thermal management, AI shines for spacecraft where heat dissipation is paramount. Simulations of satellite panels, factoring in chip layouts and environmental exposures, drop from 20 minutes to tens of milliseconds. This real-time capability extends to vibrations and multi-physics interactions, vital for missions enduring launch stresses or orbital extremes.

Penn State’s Computational Systems Design Laboratory (CSDL) pushes boundaries further with multifidelity methods. These AI-driven approaches blend low-fidelity approximations (quick but rough) with high-fidelity physics models (precise but slow). For non-critical decisions, AI leans on the cheap option; for pivotal ones, it queries the expensive model sparingly. In one project, this reduced evaluation costs for aircraft configurations, evaluating hundreds of alternatives affordably. Imagine designing a new engine: AI predicts thrust variations across velocities, flagging inefficiencies early and saving billions, as seen in the Boeing 787’s protracted development.

Bullet points highlight key simulation benefits:

- Speed Gains: Real-time flight envelope computations, from days to seconds, covering velocity and angle ranges.

- Accuracy Boost: ML models calibrated on real data minimize errors, enhancing safety predictions.

- Scalability: Handles complex geometries like UAV swarms or hypersonic vehicles.

- Integration Ease: Seamlessly plugs into CAD tools, streamlining engineer workflows.

Such advancements aren’t isolated; they’re weaving into everyday practice, where AI copilots interpret natural language commands, automating data pulls or visualization tweaks.

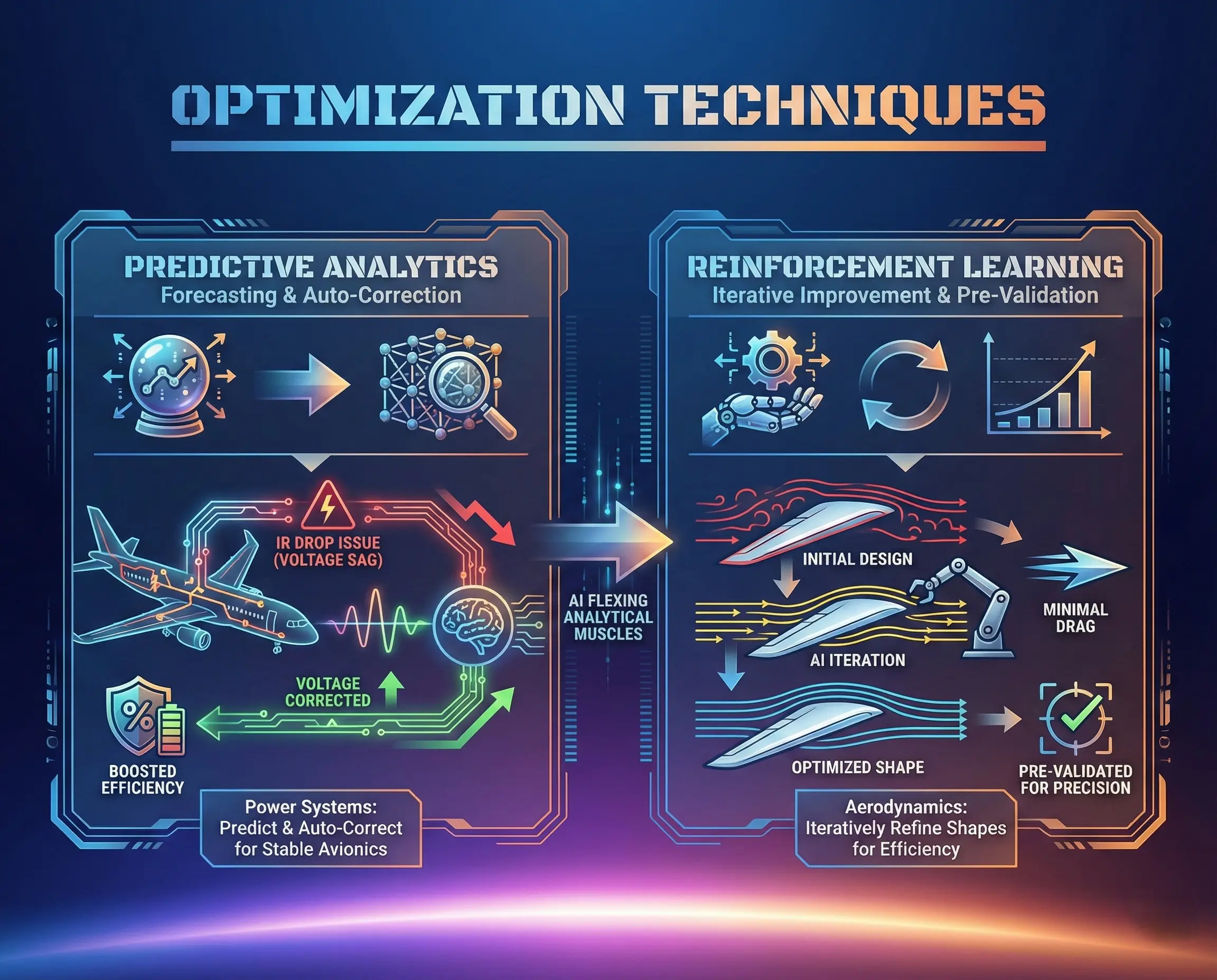

Optimization Techniques: Fine-Tuning for Peak Performance

Optimization is where AI truly flexes its analytical muscles, refining designs across disciplines. Predictive analytics forecast material behaviors under stress, while reinforcement learning iteratively improves layouts, much like training a digital apprentice.

In power systems, tools predict and auto-correct IR drop issues—voltage sags that could cripple avionics—boosting efficiency without manual overhauls. For aerodynamics, AI optimizes shapes for minimal drag, as in Boeing’s robotic assembly lines, where designs are pre-validated for precision drilling.

A table of common optimization techniques in aerospace AI:

| Technique | Description | Aerospace Application Example | Efficiency Gain Example |

|---|---|---|---|

| Predictive Analytics | Uses historical data to forecast outcomes | Fuel consumption modeling for jet engines | 5-10% reduction in burn |

| Reinforcement Learning | Learns optimal actions through trial-and-error simulation | Wing flap positioning for varying loads | 15% improvement in lift |

| Neural Network Surrogates | Approximates complex physics models | Thermal stress in satellite electronics | 100x faster predictions |

| Multi-Objective Optimization | Balances competing goals (e.g., cost vs. durability) | Fuselage material selection | 20% weight savings |

| Probabilistic Methods | Accounts for uncertainties in inputs | Risk assessment for launch vehicle trajectories | 30% faster decision cycles |

These methods ensure designs aren’t just good—they’re exceptional, tailored to real-world demands.

Real-World Case Studies: AI in Action at Leading Organizations

No discussion of AI in aerospace design is complete without spotlighting pioneers. NASA’s embrace of generative AI for Evolved Structures isn’t just innovative; it’s practical, yielding deployable hardware for diverse missions. By prompting AI with mission specs, engineers generate code-compliant components, from balloon payloads to rover arms, accelerating NASA’s ambitious timelines.

Airbus’s AI assistant for manufacturing instructions exemplifies practical integration. Engineers query in plain English—”What torque tool for this bolt?”—bypassing dense manuals, cutting response times dramatically. In aerodynamics, their platform enables fluid dynamics explorations that inform the next A350 iterations, enhancing range and eco-friendliness.

Boeing leverages AI for digital twins, virtual replicas that simulate entire aircraft lifecycles. In the T-7A Red Hawk trainer, model-based engineering halved assembly hours, with 3D models guiding every step from design to maintenance. For the MQ-25 unmanned refueler, AI ensures specs alignment, reducing errors in unmanned ops.

These cases reveal a pattern: AI amplifies human expertise, not replaces it. At GE Aerospace, digital twins monitor engine data in real time, feeding back into design loops for iterative upgrades.

Tools and Technologies Powering the Shift

Aerospace engineers rely on a suite of AI tools, from open-source libraries to proprietary platforms. Celsius Studio tackles thermal co-simulation, uncovering heat issues early via generative tweaks. Voltus InsightAI automates power fixes, while Verisium verifies complex systems, slashing debug times.

At the hardware level, NVIDIA GPUs supercharge these, enabling high-fidelity runs on the Millennium M2000. Software like Neural Concept Shape interprets CAD files, learning physics via deep learning for instant shape evaluations.

Engineers often start with ML frameworks for custom models, scaling to agentic AI for autonomous workflows. This ecosystem lowers barriers, letting even mid-sized firms compete with giants.

The Benefits: Efficiency, Safety, and Sustainability

The payoffs are profound. AI trims R&D cycles by 30-50%, per industry reports, freeing resources for bold projects. Safety surges with precise failure predictions, averting catastrophes. Sustainability? Optimized designs cut emissions— a 1% fuel save across a fleet equals thousands of tons of CO2 averted yearly.

Economically, lighter structures slash launch costs by dollars per kilogram, vital for space ventures. Operationally, predictive tools extend component life, minimizing downtime.

Yet, benefits extend to talent: AI copilots teach novices by mirroring expert flows, bridging skills gaps in a field hungry for 200,000 new roles annually.

Navigating Challenges: Ensuring Responsible AI Adoption

For all its promise, AI introduces hurdles. Data fragmentation—scattered across silos—demands robust integration, while security risks loom large; adversarial attacks could skew models. Explainability is paramount for certification, as regulators demand traceable decisions to safeguard lives.

Ethical quandaries arise, too: Who owns AI-generated designs? How to mitigate biases in training data? Solutions include human-in-the-loop protocols, rigorous audits, and investments in reliability engineering.

Adoption barriers persist—upskilling engineers, validating against standards like DO-178C—but agile pilots, like AI-orchestrated testing, reducing cycles by 30%, prove scalable paths forward.

Future Trends: Toward AI-Native Aerospace Engineering

Looking ahead, AI will evolve into native workflows: Autonomous verification against regs, cobots in assembly, and geospatial models processing satellite data 3-4x faster. By 2040, machines may author most embedded code, per NASA’s visions.

Hypersonics and urban air mobility will lean on AI for real-time adaptations, while ethical AI frameworks ensure equitable progress. Engineers, armed with master’s-level AI proficiency, will lead this charge, blending computation with creativity.

In sum, AI isn’t just a tool—it’s the co-pilot steering aerospace toward a smarter, safer sky. As these technologies mature, expect designs that defy gravity in ways we once deemed impossible, propelling humanity further into the cosmos.

Key Citations And References

- Neural Concept on AI in Aerospace Design

- Cadence AI for Aerospace

- Rutgers on AI Revolution in Engineering

- Penn State CSDL on Scalable AI

- A2 Global on Generative AI in Aerospace

- Airbus on Generative AI

- Boeing on Digital Thread

Read These Articles in Detail

- Aerospace Engineering vs. Mechanical Engineering

- The Future of Aerospace Propulsion Systems

- How Aerospace Education Is Adapting to Industry Demands

- The Role of Aerospace in Combating Climate Change

- Aerospace Radar Technology: Past, Present, and Future

- The Role of Aerospace in National Security Strategies

- The Role of Nanotechnology in Aerospace Materials

- Aerospace Materials: Stronger, Lighter, And Smarter

- Aerospace Engineering Explained: A Beginner’s Guide

- Electric Aircraft vs. Hydrogen Aircraft: Which Is More Sustainable?

- Hypersonic Weapons: Aerospace’s New Arms Race

- Aerospace Defense Systems: From Drones to Hypersonic Missiles

- How Aerospace Engineers Reduce Fuel Consumption

- Computational Fluid Dynamics in Aerospace Innovation

- The Global Aerospace Market Outlook: Trends and Forecasts

- Satellite Surveillance: Aerospace’s Role in Modern Warfare

- How Aerospace Companies Are Reducing Environmental Impact

- How Airlines Use Aerospace Data Analytics to Cut Costs

- Aerospace Engineering Challenges: Innovation and Sustainability

- The Role of CFD in Aerospace Engineering

- The Role of Women in Aerospace: Breaking Barriers in the Skies

- Sustainable Aviation Fuels: The Aerospace Industry’s Green Bet

- Aerospace Cybersecurity: Protecting the Skies from Digital Threats

- Aerospace Trends Driving the Next Generation of Airliners

- The Rise of Autonomous Aerospace Systems

- How to Start a Career in Aerospace Engineering

- Can Aerospace Go Carbon Neutral by 2050?

- The Role of Aerospace in Missile Defense Systems

- How Aerospace Engineers Use AI in Design

- Top 10 Aerospace Engineering Innovations of the Decade

- Top Aerospace Careers in 2025 and Beyond

- How Aerospace Innovations Shape Global Defense Policies

- Hydrogen-Powered Aircraft: The Next Green Revolution

- Top 10 Emerging Aerospace Technologies Transforming the Industry

- The Future of Hypersonic Flight: Challenges and Opportunities

- How AI Is Revolutionizing Aerospace Engineering

- Additive Manufacturing in Aerospace: 3D Printing the Future of Flight

- The Rise of Electric Aircraft: Are We Ready for Zero-Emission Aviation?

- Aerospace Materials of Tomorrow: From Composites to Nanotechnology

- Digital Twins in Aerospace: Reducing Costs and Improving Safety

- The Role of Robotics in Modern Aerospace Manufacturing

- Quantum Computing Applications in Aerospace Design

- How Augmented Reality Is Changing Aerospace Training

- Space Tethers Explained: The Next Leap in Orbital Mechanics

- Ion Propulsion vs. Chemical Rockets: Which Will Power the Future?

- The Role of Nuclear Propulsion in Deep Space Missions

- Space Mining: The Aerospace Industry’s Next Gold Rush

- How Reusable Rockets Are Reshaping the Space Economy

- The Artemis Program: NASA’s Return to the Moon

- Space Tourism: Business Model or Billionaire’s Playground?

- How Aerospace Startups Are Disrupting Commercial Aviation

- The Economics of Low-Cost Airlines in the Aerospace Era

- Urban Air Mobility: The Rise of Flying Taxis

- The Future of Mars Colonization: Key Aerospace Challenges and Solutions Ahead

- CubeSats and Small Satellites: Democratizing Space Access

- The Future of Cargo Drones in Global Logistics

- The Role of Aerospace in Building a Lunar Economy

Frequently Asked Questions

FAQ 1: What Is Generative Design and How Does It Transform Aerospace Engineering?

Generative design represents a powerful shift in how aerospace engineers approach creating aircraft and spacecraft components. At its heart, this generative design process involves inputting specific constraints—like weight limits, material properties, and performance goals—into an AI system, which then automatically produces a wide array of potential solutions. Unlike traditional methods where engineers manually sketch and refine ideas, generative design uses algorithms inspired by natural evolution to explore thousands of variations quickly, selecting the most efficient ones based on predefined criteria. This not only sparks innovation but also ensures that designs are optimized for real-world demands, such as reducing fuel consumption or enhancing structural durability.

In aerospace applications, generative design shines in crafting lightweight yet robust parts, crucial for missions where every ounce matters. For example, engineers might use it to develop intricate lattice structures for satellite frames or wing reinforcements that mimic bone patterns for better stress distribution. The result is components that are up to 30 percent lighter without compromising safety, directly contributing to more efficient launches and longer flight ranges. As AI evolves, this tool is becoming integral to early-stage prototyping, allowing teams to iterate faster and integrate multi-objective factors like aerodynamics and thermal resistance seamlessly.

Beyond speed, generative design fosters creativity by challenging conventional geometries, leading to breakthroughs in areas like hypersonic vehicles or urban air mobility drones. However, it requires careful human oversight to ensure manufacturability and compliance with strict regulations. Overall, it’s redefining aerospace engineering as a collaborative dance between human intuition and machine precision, paving the way for the next era of flight.

FAQ 2: How Does AI Speed Up Simulations in Aerospace Design Processes?

AI dramatically accelerates simulations in aerospace design by replacing lengthy, resource-intensive computations with intelligent approximations that deliver near-instant results. Traditional computational fluid dynamics (CFD) and finite element analysis (FEA) can take hours or even days to model airflow over a wing or stress on a fuselage, limiting how many iterations engineers can test. AI introduces surrogate models—neural networks trained on historical simulation data—that predict outcomes in milliseconds, enabling real-time adjustments during design reviews.

This speedup is particularly vital for complex projects like engine optimization or satellite thermal management, where multi-physics interactions must be balanced. Recent advancements, such as multi-fidelity methods, further enhance this by blending quick low-accuracy models with precise high-fidelity ones only when needed, cutting overall costs by up to 50 percent. In practice, teams can now evaluate thousands of design variants in a single session, uncovering subtle improvements in lift or vibration resistance that might otherwise go unnoticed.

To illustrate the transformation, consider the following comparison of traditional versus AI-enhanced simulation workflows:

| Aspect | Traditional Simulation Methods | AI-Enhanced Simulation Methods |

|---|---|---|

| Processing Time | Hours to days per run, requiring supercomputers | Milliseconds to minutes, using standard hardware |

| Number of Iterations | Limited to dozens due to time constraints | Thousands, supporting rapid prototyping |

| Accuracy Maintenance | High but at the cost of exhaustive validation | Comparable, with error rates under 5% via training |

| Resource Usage | High computational power and energy consumption | Reduced by 70-90%, enabling cloud-based scalability |

| Example Application | Wind tunnel validation for wing shapes | Real-time drag optimization for UAV swarms |

| Overall Efficiency Gain | Baseline for historical projects | Up to 10,000-fold speedup in prediction cycles |

This table highlights how AI not only saves time but also democratizes advanced simulations for smaller aerospace firms, fostering broader innovation in the field.

FAQ 3: What Are the Key Benefits of Integrating AI into Aerospace Engineering Design?

Integrating artificial intelligence (AI) into aerospace engineering design offers a multitude of benefits that extend from cost savings to enhanced safety, making it an indispensable ally for modern projects. One primary advantage is the dramatic reduction in development timelines; what once took months of manual iterations can now be achieved in days, allowing engineers to focus on high-level innovation rather than repetitive calculations. This efficiency translates to lower R&D expenses, often by 30 to 50 percent, freeing up budgets for ambitious endeavors like sustainable aviation fuels or reusable launch systems.

Beyond speed, AI bolsters design quality through precise optimizations that humans might overlook. For instance:

- Improved Aerodynamics: AI refines shapes to minimize drag, potentially boosting fuel efficiency by 5 to 10 percent across commercial fleets.

- Enhanced Structural Integrity: Predictive models simulate extreme conditions, identifying weaknesses early and reducing failure risks in high-stakes environments like space travel.

- Sustainability Gains: Optimized components lead to lighter aircraft, cutting carbon emissions equivalent to thousands of tons annually per airline operator.

- Scalability for Complex Systems: AI handles vast datasets from digital twins, enabling holistic views of entire aircraft lifecycles from cradle to grave.

These benefits collectively drive a more resilient industry, where AI not only streamlines workflows but also empowers engineers to tackle global challenges like climate change and rapid urbanization. As adoption grows, the ripple effects—safer skies, greener flights, and accelerated space exploration—promise to reshape transportation for generations to come.

FAQ 4: Which Major Aerospace Companies Are Leading the Way in AI-Driven Design Innovations?

Several leading aerospace giants are at the forefront of leveraging AI to revolutionize design practices, turning conceptual sketches into production-ready marvels with remarkable speed and precision. Companies like Airbus have pioneered AI platforms that integrate generative tools directly into their engineering suites, allowing teams to explore fuselage and wing variants that balance weight, strength, and thermal performance. Their efforts have resulted in prototypes for next-generation aircraft that promise up to 1 percent better fuel economy, a modest figure that scales massively across global operations.

NASA stands out for its bold applications, particularly in the Evolved Structures initiative, where AI generates lightweight components for space instruments and planetary rovers. These designs, often featuring organic lattice patterns, have lightened hardware by a third while maintaining rigorous safety standards, accelerating missions from telescopes to atmospheric probes. Meanwhile, Boeing employs AI for digital twins—virtual replicas of entire aircraft—that simulate lifecycles and optimize assembly, as seen in the T-7A Red Hawk trainer, where production times were halved through predictive validations.

Other innovators include GE Aerospace, which uses AI to monitor engine data in real time and feed insights back into design loops for continuous refinement, and emerging players focusing on urban air mobility who rely on AI for drone swarm aerodynamics. These companies exemplify a collaborative ecosystem where AI amplifies expertise, ensuring that advancements in design not only push technological boundaries but also align with practical, regulatory, and environmental imperatives.

FAQ 5: What Challenges Arise When Implementing AI in Aerospace Design and How Can They Be Overcome?

Implementing AI in aerospace design brings exciting possibilities, but it also introduces several hurdles that engineers must navigate to fully harness its potential. One major challenge is data fragmentation, where vital information is siloed across teams or legacy systems, making it hard for AI models to train effectively on comprehensive datasets. This can lead to incomplete predictions, especially in safety-critical areas like material fatigue analysis. Another issue is the black-box nature of some AI algorithms, which complicates regulatory certification since authorities require transparent decision-making to verify compliance with standards like DO-178C.

Additionally, cybersecurity risks loom large; as AI systems process sensitive design blueprints, they become prime targets for adversarial attacks that could subtly alter outputs and compromise aircraft integrity. Skill gaps among engineers further slow adoption, with many needing upskilling in machine learning to integrate AI seamlessly into workflows.

The good news is that targeted strategies can address these obstacles effectively. The following table outlines common challenges alongside practical solutions:

| Challenge | Description | Potential Solutions |

|---|---|---|

| Data Fragmentation | Scattered datasets hinder model accuracy | Implement unified data platforms with API integrations for real-time access |

| Model Explainability | Opaque AI decisions raise certification barriers | Adopt interpretable AI techniques like decision trees and human-in-the-loop reviews |

| Cybersecurity Risks | Vulnerabilities in AI pipelines expose designs | Deploy encryption, regular audits, and adversarial training for robust defenses |

| Skill Gaps | Engineers lack AI proficiency for effective use | Offer targeted training programs and collaborative tools with intuitive interfaces |

| High Initial Costs | Setup for AI infrastructure demands significant investment | Start with pilot projects on cloud-based services to scale gradually and measure ROI |

By proactively tackling these issues through iterative pilots and cross-disciplinary collaboration, aerospace firms can mitigate risks and unlock AI’s full transformative power.

FAQ 6: What Essential Tools and Technologies Are Aerospace Engineers Using with AI for Design?

Aerospace engineers are increasingly relying on a diverse array of AI-powered tools and technologies to streamline design workflows, from initial concepting to final validation. These solutions blend seamlessly with existing software like CAD systems, enhancing rather than replacing traditional methods. For generative design, platforms that automate geometry exploration stand out, enabling quick generation of optimized parts based on multi-objective inputs such as aerodynamics and manufacturability.

In simulation acceleration, surrogate modeling tools use neural networks to approximate complex physics, slashing computation times while maintaining accuracy. Engineers also turn to digital twin technologies, which create virtual replicas for ongoing testing and refinement. Optimization suites powered by reinforcement learning further refine parameters like engine thrust or wing flaps, iterating through scenarios autonomously.

Key tools in this ecosystem include:

- AI-Driven CAD Extensions: Plugins that suggest modifications in real time, ideal for fuselage layouts.

- Multi-Physics Simulators: Integrated environments handling fluids, structures, and electromagnetics with AI surrogates.

- Predictive Analytics Platforms: For forecasting material behaviors under extreme conditions, crucial for space applications.

- Cloud-Based Collaboration Hubs: Facilitating team access to AI models without heavy local hardware.

These technologies not only boost productivity but also foster innovation, allowing engineers to experiment boldly while ensuring designs meet stringent aerospace standards.

FAQ 7: How Is AI Contributing to Sustainability Efforts in the Aerospace Industry?

AI is playing a pivotal role in advancing sustainability within the aerospace industry by enabling designs that minimize environmental impact without sacrificing performance. Through optimization algorithms, AI helps create lighter structures that reduce fuel consumption—a critical factor since aviation accounts for about 2 percent of global CO2 emissions. For instance, generative design can yield components that cut aircraft weight by 20 to 30 percent, directly translating to lower operational emissions over a plane’s lifecycle.

This extends to lifecycle management, where AI-powered digital twins predict maintenance needs, extending part longevity and reducing waste from premature replacements. In propulsion systems, machine learning models optimize engine efficiency, exploring hybrid or electric configurations that align with net-zero goals by 2050. Recent initiatives even use AI to simulate sustainable materials like bio-composites, ensuring they withstand flight stresses while being recyclable.

As the industry faces pressure to decarbonize, AI’s ability to balance trade-offs—such as cost versus eco-friendliness—positions it as a cornerstone of green innovation. By integrating these tools early in design phases, aerospace engineers are not just meeting regulations but actively driving a shift toward cleaner, more responsible skies for future generations.

FAQ 8: What Does the Future Hold for AI in Aerospace Engineering Design?

The future of AI in aerospace engineering design looks incredibly promising, with emerging trends pointing toward fully autonomous workflows and unprecedented levels of integration. By the end of the decade, agentic AI—systems that independently plan and execute design tasks—could handle everything from regulatory compliance checks to multi-disciplinary optimizations, freeing engineers for creative problem-solving. This evolution will be fueled by advancements in high-performance computing, making real-time simulations of entire missions feasible on everyday hardware.

Looking further ahead, AI will deepen its synergy with immersive technologies like virtual reality, allowing teams to “walk through” designs virtually and refine them collaboratively across continents. Sustainability will remain central, with AI optimizing for circular economies, such as designs that facilitate easy disassembly for recycling.

Anticipated developments include:

- Autonomous Verification: AI agents cross-referencing designs against global standards in seconds.

- Hypersonic Innovations: Predictive models for ultra-fast travel, addressing thermal and material challenges.

- Urban Air Mobility: Swarm intelligence for drone traffic management in cityscapes.

- Space Exploration: AI-orchestrated architectures for habitats on Mars or the Moon.

While ethical considerations like bias mitigation will shape adoption, the trajectory suggests AI will propel aerospace into an era of efficiency, exploration, and equity.

FAQ 9: In What Ways Does AI Design Differ from Traditional Aerospace Engineering Methods?

AI design in aerospace engineering marks a profound departure from traditional methods, shifting from labor-intensive, linear processes to dynamic, data-driven explorations. Conventionally, engineers relied on iterative hand-sketching and physical prototypes, constrained by human bandwidth and computational limits, which often led to conservative outcomes based on past successes. AI, conversely, unleashes exponential exploration, generating diverse options algorithmically and learning from simulations to evolve superior solutions.

This difference manifests in scope and speed: Traditional approaches might yield a handful of variants over weeks, while AI delivers thousands in hours, incorporating variables like climate variability or supply chain fluctuations. The result is more adaptive designs, resilient to uncertainties that rigid methods overlook.

A clear comparison reveals these shifts:

| Dimension | Traditional Methods | AI-Driven Methods |

|---|---|---|

| Design Exploration | Manual, limited to expert intuition | Algorithmic, exhaustive across vast parameter spaces |

| Iteration Cycle | Weeks or months, with physical testing | Hours or days, via virtual surrogates |

| Outcome Predictability | Relies on historical analogies | Probabilistic, accounting for real-time uncertainties |

| Innovation Potential | Incremental improvements on established norms | Disruptive, organic geometries defying conventions |

| Cost and Resource Use | High due to prototypes and trial-and-error | Lower, with 40-60% R&D savings through automation |

Embracing AI doesn’t eliminate traditional expertise but elevates it, blending proven principles with computational creativity for groundbreaking advancements.

FAQ 10: What Skills Should Aspiring Aerospace Engineers Develop to Work with AI in Design?

Aspiring aerospace engineers aiming to thrive in AI-integrated design must cultivate a blend of technical prowess and adaptive mindsets to navigate this rapidly evolving field. Core to this is building proficiency in machine learning fundamentals, such as understanding neural networks and data preprocessing, which empower engineers to train models for tasks like aerodynamic predictions. Hands-on experience with programming languages like Python, coupled with familiarity in libraries for simulation and optimization, forms the bedrock for implementing AI tools effectively.

Beyond code, developing an analytical eye for interpreting AI outputs is essential—knowing when to trust a generative suggestion or probe deeper ensures designs remain safe and innovative. Soft skills, including collaborative problem-solving, gain new weight as engineers increasingly work alongside AI systems and multidisciplinary teams to validate results.

To prepare, consider focusing on:

- Domain-Specific AI Applications: Courses in generative design and digital twins tailored to aerospace constraints.

- Ethical and Regulatory Knowledge: Grasping standards for AI transparency in high-stakes industries.

- Practical Project Experience: Building portfolios with simulations of real scenarios, like optimizing a drone wing.

As the demand for AI-savvy talent surges—with projections of 200,000 new roles by 2030—those who bridge classical engineering with intelligent automation will lead the charge in designing the aircraft and spacecraft of tomorrow.

FAQ 11: How Is AI Revolutionizing Materials Selection in Aerospace Design?

AI is fundamentally changing how aerospace engineers select and optimize materials, moving away from trial-and-error approaches to data-driven decisions that prioritize performance, weight, and sustainability. By analyzing vast datasets on material properties, environmental stresses, and manufacturing constraints, AI algorithms predict how composites, alloys, or advanced polymers will behave under extreme conditions like high altitudes or re-entry heat. This allows for the creation of hybrid materials that blend the best traits—such as the lightness of carbon fiber with the durability of titanium—resulting in components that are stronger yet lighter, directly enhancing fuel efficiency and payload capacity.

In practice, generative AI tools simulate molecular interactions to suggest novel material combinations, reducing the need for costly physical tests. For instance, engineers designing satellite panels can use AI to evaluate thermal expansion in zero gravity, ensuring longevity without excess weight. This not only speeds up the selection process from months to weeks but also minimizes waste, aligning with industry pushes for eco-friendly practices. As AI integrates with additive manufacturing, it further refines selections by factoring in printability, leading to bespoke parts tailored for specific aircraft or spacecraft roles.

The broader impact extends to lifecycle considerations, where AI forecasts degradation over time, helping design for recyclability. While challenges like data accuracy persist, ongoing advancements in machine learning are making material selection more intuitive, empowering engineers to innovate confidently in an industry where margins for error are slim.

FAQ 12: What Role Do Digital Twins Play in AI-Enhanced Aerospace Design?

Digital twins, virtual replicas of physical assets infused with real-time data, are becoming indispensable in AI-driven aerospace design, offering a sandbox for testing and refinement without real-world risks. Powered by AI, these twins simulate entire systems—from engines to full fuselages—under diverse scenarios, allowing engineers to predict behaviors like vibration during turbulence or heat buildup in propulsion units. This integration accelerates iteration cycles, as changes in the digital model instantly reveal impacts across interconnected components, fostering holistic optimizations.

A key advantage lies in their predictive power; AI algorithms within digital twins analyze sensor data to anticipate failures, informing upfront design choices that enhance reliability. For example, in spacecraft development, a digital twin might replicate launch vibrations, enabling adjustments to structural reinforcements before prototyping. This approach has proven to cut development costs by up to 20 percent while improving safety through exhaustive virtual stress testing.

Moreover, digital twins bridge design and operations, feeding post-flight data back into models for continuous evolution. As cloud computing advances, they enable collaborative global teams to interact with these twins in real time, democratizing expertise and speeding market entry for new aircraft concepts.

FAQ 13: What Is Agentic AI and Its Emerging Applications in Aerospace Design?

Agentic AI, an advanced form of artificial intelligence that acts autonomously to achieve goals, is poised to transform aerospace design by handling complex, multi-step tasks with minimal human input. Unlike traditional AI that responds to queries, agentic systems plan, execute, and adapt strategies independently, such as autonomously optimizing a wing’s aerodynamics by running simulations, evaluating trade-offs, and proposing refinements based on regulatory standards. In 2025, this technology is shifting from pilots to scaled use, particularly in decision-making for design workflows.

In aerospace, agentic AI excels in mission planning, where it simulates collision avoidance for drones or geospatial targeting for satellites, ensuring designs incorporate robust safety layers from the outset. Benefits include dramatic productivity gains—up to 36 percent of manufacturing tasks could be augmented—freeing engineers for creative oversight. However, its deployment requires careful governance to address regulatory hurdles, with early adopters focusing on non-critical functions like initial concept generation.

As adoption grows, agentic AI will integrate with human teams, enhancing rather than replacing expertise, and paving the way for faster innovation in areas like hypersonic vehicles. Its potential to scale across procurement and logistics underscores a future where design processes are more agile and intelligent.

FAQ 14: How Does AI Impact Supply Chain and Manufacturing in Aerospace Design?

AI is streamlining the supply chain and manufacturing phases of aerospace design by predicting disruptions, optimizing inventory, and automating production workflows, ultimately creating a seamless bridge from blueprint to build. In design, AI analyzes global supplier data to recommend materials that align with availability and cost, reducing delays in sourcing rare alloys for engine components. This predictive capability extends to manufacturing, where AI-driven simulations forecast production bottlenecks, enabling proactive adjustments like rerouting parts for just-in-time assembly.

A notable application is in defect detection during fabrication; machine learning models inspect welds or composites in real time, flagging issues that could compromise structural integrity and saving rework costs. For instance, in aircraft assembly, AI optimizes robotic paths for precision riveting, cutting assembly times while maintaining quality. These efficiencies not only lower expenses—potentially by 15 to 25 percent—but also enhance sustainability by minimizing scrap and energy use.

To highlight the transformations, consider this overview of AI’s influence:

| Aspect | Traditional Approach | AI-Enhanced Approach |

|---|---|---|

| Supply Chain Forecasting | Manual reviews of historical data | Predictive analytics for real-time risk assessment |

| Inventory Management | Static stocking based on estimates | Dynamic optimization reducing excess by 20-30% |

| Defect Detection | Post-production inspections | In-line AI monitoring with 95% accuracy |

| Production Scheduling | Spreadsheet-based planning | Autonomous adjustments for workflow efficiency |

| Cost Reduction | Incremental through experience | Targeted savings via simulation-driven tweaks |

This integration ensures designs are not only innovative but also feasible at scale, supporting the industry’s recovery and growth.

FAQ 15: In What Ways Does AI Support Predictive Maintenance During the Design Phase?

AI’s role in predictive maintenance begins early in the design phase, embedding foresight into components to anticipate wear and failures long before they occur, which revolutionizes how aerospace engineers build longevity into their creations. By leveraging historical failure data and simulation models, AI identifies potential weak points—such as fatigue in landing gear under repeated cycles—and suggests reinforcements, like adaptive damping systems that adjust to usage patterns. This proactive stance shifts design from reactive fixes to inherent resilience, extending service life and reducing operational downtimes.

During conceptualization, AI tools create probabilistic models that simulate thousands of flight hours, forecasting maintenance needs and informing choices in materials or geometries. For example, in turbine blade design, AI might predict erosion from particle ingestion, recommending coatings that halve inspection intervals. The result is aircraft that require fewer interventions, translating to billions in savings for fleets and greener operations through less frequent part replacements.

Beyond immediate benefits, this approach fosters a feedback loop where in-service data refines future designs, creating evolving standards of reliability. As sensors become ubiquitous, AI’s predictive edge will only sharpen, making maintenance a design feature rather than an afterthought.

FAQ 16: What Ethical Considerations Should Aerospace Engineers Address When Using AI in Design?

When incorporating AI into aerospace design, engineers must grapple with ethical considerations to ensure innovations prioritize safety, equity, and transparency in an industry where lives and environments hang in the balance. A primary concern is algorithmic bias; if training data skews toward certain flight regimes or demographics, designs might underperform in underrepresented scenarios, such as extreme weather in developing regions. To counter this, diverse datasets and regular audits are essential, promoting inclusive outcomes that serve global users equitably.

Another layer involves accountability: Who bears responsibility if an AI-optimized part fails due to unforeseen model limitations? Clear protocols, including human oversight in critical decisions, help delineate roles and build trust. Privacy also emerges, as AI processes sensitive proprietary designs, necessitating robust cybersecurity to prevent intellectual theft or sabotage.

Engineers can navigate these by adopting frameworks that embed ethics from the start:

- Bias Mitigation: Use balanced data sources and fairness metrics during model validation.

- Transparency Tools: Employ explainable AI to trace design decisions back to inputs.

- Stakeholder Engagement: Involve ethicists and end-users in review cycles for broader perspectives.

- Sustainability Focus: Prioritize designs that minimize environmental harm, aligning with global standards.

By weaving these principles into workflows, AI becomes a force for responsible progress, upholding the aerospace sector’s commitment to excellence.

FAQ 17: How Are Aerospace Companies Investing in Training for AI Design Tools?

Aerospace companies are ramping up investments in training programs to equip engineers with the skills needed to harness AI design tools effectively, recognizing that technical prowess alone won’t suffice in this data-centric era. These initiatives often blend online modules, hands-on workshops, and certifications, focusing on practical applications like interpreting generative outputs or debugging surrogate models. For mid-career professionals, tailored bootcamps simulate real projects, such as optimizing a drone’s propulsion, to bridge knowledge gaps swiftly.

The push stems from a talent crunch; with demand for AI-literate engineers surging, firms partner with universities for customized curricula that integrate aerospace specifics with machine learning basics. Benefits include faster adoption rates—teams trained in AI simulations report 25 percent quicker project timelines—and innovation boosts, as upskilled staff experiment boldly.

Key training components include:

- Core AI Literacy: Basics of neural networks and data ethics.

- Tool-Specific Mastery: Proficiency in platforms for CFD acceleration or material prediction.

- Collaborative Simulations: Group exercises mimicking multidisciplinary design sprints.

- Continuous Learning: Access to update tracks on emerging trends like agentic systems.

This strategic focus not only future-proofs workforces but also cultivates a culture where AI amplifies human ingenuity, driving competitive edges in a fast-evolving field.

FAQ 18: How Does AI Application in Aerospace Design Compare to the Automotive Sector?

AI’s application in aerospace design shares synergies with automotive but diverges due to aerospace’s unforgiving safety thresholds and scale, yet both sectors leverage it for optimization and efficiency. In automotive, AI excels in rapid prototyping for electric vehicle batteries, using generative tools to iterate shapes for better range, much like aerospace’s wing refinements for drag reduction. However, aerospace demands hyper-accurate simulations for hypersonic stresses, contrasting automotive’s focus on consumer variability like crash dynamics.

Cross-pollination is evident: Techniques from automotive digital twins inform aerospace lifecycle modeling, while aerospace’s rigorous validation processes enhance automotive autonomy testing. Cost-wise, AI yields similar 20-30 percent R&D savings, but aerospace’s longer cycles amplify returns through fewer certification hurdles.

A comparative table illustrates these parallels and distinctions:

| Category | Aerospace Design | Automotive Design |

|---|---|---|

| Primary Focus | Safety, lightweight structures, extreme conditions | Efficiency, scalability, consumer integration |

| AI Simulation Speed | 500x gains for fluid dynamics | 100x for crash and thermal modeling |

| Key Challenge | Regulatory certification delays | Supply chain volatility for mass production |

| Innovation Example | Thruster nozzles via surrogate models | Aerodynamic panels for EVs |

| Shared Benefit | Reduced prototyping costs by 25% | Enhanced sustainability through material optimization |

This interplay accelerates advancements, with lessons from one fueling breakthroughs in the other.

FAQ 19: What Regulatory Challenges Does AI Face in Aerospace Design Certification?

Regulatory challenges in certifying AI-driven aerospace designs stem from the need to prove reliability in high-stakes environments, where even minor flaws can cascade into disasters. Bodies like the FAA and EASA require exhaustive traceability, yet AI’s opaque decision-making—often termed the black box—complicates demonstrating compliance with standards such as DO-178C for software assurance. This leads to extended validation periods, as regulators demand evidence that AI outputs consistently meet safety margins under all variables.

To address this, industry consortia are developing guidelines for explainable AI, mandating documentation of training data and model behaviors. Pilot programs test hybrid certifications, blending AI efficiencies with human-verified benchmarks, which could shorten approvals from years to months. Meanwhile, international harmonization efforts aim to unify rules, easing global deployments.

Overcoming these hurdles involves:

- Standardized Frameworks: Protocols for auditing AI pipelines.

- Risk-Based Approaches: Tiered scrutiny based on application criticality.

- Collaborative Testing: Joint regulator-industry simulations for trust-building.

As these evolve, they promise to unlock AI’s potential while safeguarding the skies.

FAQ 20: What Emerging Trends Involve Immersive Technologies with AI in Aerospace Design?

Emerging trends blending immersive technologies like virtual and augmented reality with AI are reshaping aerospace design by enabling intuitive, collaborative explorations of complex models in three dimensions. AI generates dynamic environments where engineers “walk through” fuselages or manipulate wing geometries virtually, receiving instant feedback on aerodynamics or stress points, which accelerates ideation and reduces miscommunications in team settings.

This fusion enhances training too, with VR simulations powered by AI replicating flight scenarios for design validation, cutting physical mockup needs. In 2025, additive manufacturing integrates seamlessly, as AR overlays AI-optimized blueprints onto printers for precise builds. Benefits include 40 percent faster reviews and broader accessibility for remote experts.

Looking ahead, these trends will expand to mixed-reality cockpits for human-AI co-design, fostering innovations in urban air taxis. By merging sensory immersion with computational smarts, they make abstract designs tangible, propelling aerospace toward more inclusive and rapid development.