Imagine soaring through the skies in an aircraft that’s lighter than ever before, yet stronger and more efficient, cutting fuel use by up to 20 percent while slashing emissions. Or picture a spacecraft re-entering Earth’s atmosphere, its hull unscathed by blistering heat exceeding 1,600 degrees Celsius, thanks to materials engineered at the tiniest scales. This isn’t science fiction—it’s the reality being forged today in aerospace engineering labs around the world.

As the industry races toward sustainable, high-performance flight and deeper space exploration, the materials we build with are evolving faster than ever. At the heart of this transformation are advanced composites and nanotechnology, two pillars that promise to redefine what’s possible in the air and beyond. From the sleek fuselages of commercial jets to the resilient structures of hypersonic vehicles, these innovations are not just improving performance; they’re enabling entirely new missions, like urban air mobility and Mars colonization.

In this deep dive, we’ll explore how these materials work, their real-world impacts, and the exciting horizon ahead.

Table of Contents

The Evolution of Aerospace Materials

Aerospace has always pushed materials to their limits, starting with wood and fabric in the Wright brothers’ era, then aluminum alloys that dominated mid-20th-century jets for their balance of strength and workability. But as demands grew—for faster speeds, longer ranges, and greener operations—engineers turned to composites in the 1970s and 1980s. These hybrid wonders, blending fibers like carbon or glass with resin matrices, offered a game-changing strength-to-weight ratio, often five times better than metals.

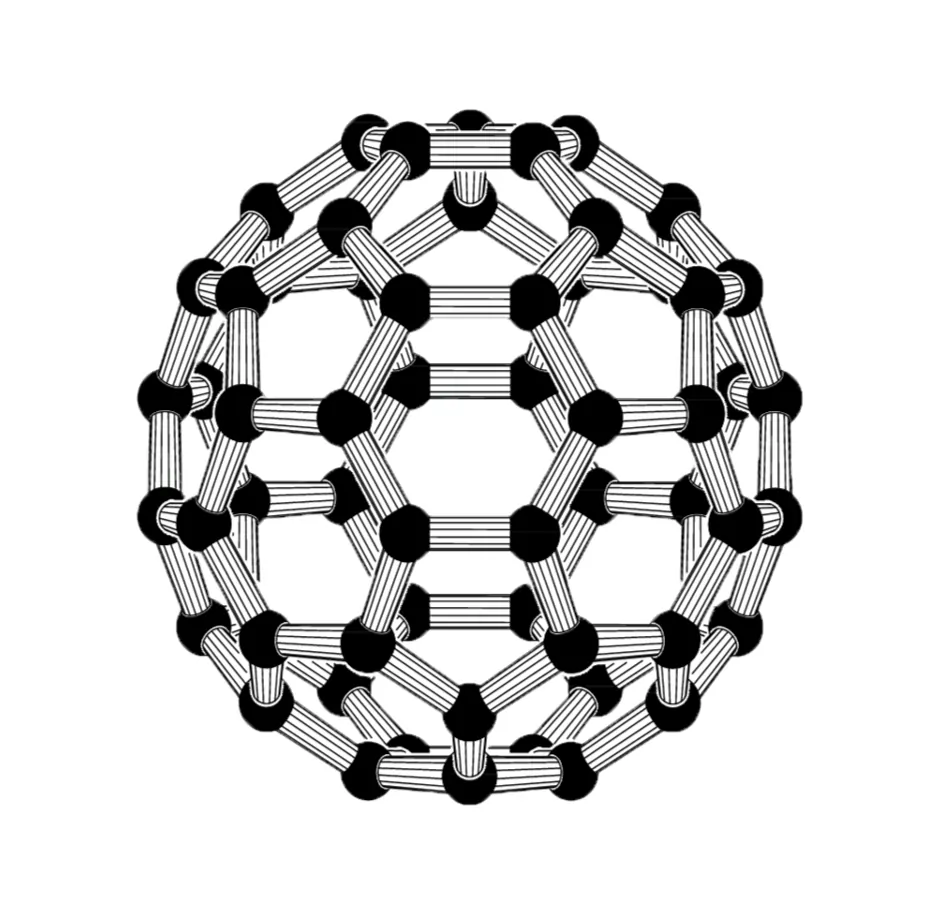

Today, with global air traffic projected to double by 2040, the pressure is on for even smarter materials. Enter nanotechnology, which manipulates matter at the atomic level to unlock properties unattainable in bulk forms. What began as lab curiosities, like carbon nanotubes (CNTs) discovered in 1991, are now integral to prototypes that could make electric vertical takeoff and landing (eVTOL) vehicles a daily sight in cities.

This evolution isn’t linear; it’s a fusion. Composites provide the structural canvas, while nano-elements add multifunctional smarts—like self-healing cracks or embedded sensors for real-time health monitoring. The result? Aircraft that last longer, cost less to maintain, and burn far less fuel. According to industry forecasts, the aerospace composites market alone will surge from $25 billion in 2025 to $45 billion by 2033, driven by these synergies. As we unpack the details, it’s clear: the materials of tomorrow aren’t just tougher; they’re smarter, greener, and ready for the stars.

Advanced Composites: Building Lighter, Tougher Skies

Composites have become the unsung heroes of modern aerospace, comprising up to 50 percent of an aircraft’s primary structure in cutting-edge designs. At their core, these materials layer high-strength fibers within a polymer, metal, or ceramic matrix, creating a seamless blend of rigidity and flexibility. Carbon fiber reinforced polymers (CFRP) lead the pack, prized for their density that’s just one-fifth of steel yet yielding strengths over 550 MPa. Why does this matter? Every kilogram saved translates to thousands of dollars in annual fuel savings per plane—critical as airlines grapple with rising costs and carbon taxes.

Take the shift toward sustainability: bio-based composites, derived from plant fibers like flax or hemp, are emerging as eco-alternatives to petroleum-derived resins. These not only reduce lifecycle emissions by up to 50 percent but also offer comparable fatigue resistance for non-critical parts like interior panels. Meanwhile, ceramic matrix composites (CMCs) shine in extreme heat zones, such as turbine blades, where they endure temperatures 300 degrees higher than nickel superalloys without melting. Manufacturing advances, like automated fiber placement (AFP) and 3D printing, have slashed production times by 30 percent, making these materials viable for high-volume runs.

Key Types of Aerospace Composites and Their Strengths

To grasp their versatility, consider the spectrum:

- Polymer Matrix Composites (PMCs): Dominant in fuselages and wings, offering easy molding and corrosion resistance. Example: The Boeing 787’s wings, where CFRP reduces weight by 20 percent over aluminum, boosting range to 8,500 nautical miles.

- Metal Matrix Composites (MMCs): Infused with titanium or aluminum matrices for engine components, they excel in vibration damping. A real-world win: GE Aviation’s LEAP engine uses MMC fan blades that cut fuel burn by 15 percent.

- Ceramic Matrix Composites (CMCs): Heat wizards for nozzles and shrouds, with oxidation resistance up to 1,200 degrees Celsius. NASA’s X-59 quiet supersonic jet prototypes leverage CMCs for stealthy, efficient flight.

- Hybrid Composites: Blending fibers for tailored properties, like glass-carbon mixes for cost-effective interiors.

These aren’t theoretical; they’re flying today. The Airbus A350 XWB, with 53 percent composites by weight, achieves 25 percent better fuel efficiency than its predecessors, proving how these materials turn environmental mandates into competitive edges.

| Composite Type | Key Properties | Density (g/cm³) | Tensile Strength (MPa) | Primary Applications | Weight Savings vs. Metal (%) |

|---|---|---|---|---|---|

| CFRP | High stiffness, low thermal expansion | 1.5-1.8 | 500-2000 | Fuselages, wings | 40-50 |

| CMC | Extreme heat tolerance, low erosion | 2.5-3.5 | 200-400 | Turbine blades, heat shields | 30-40 |

| MMC | Superior wear resistance, conductivity | 2.7-4.5 | 300-1000 | Engine casings, landing gear | 20-30 |

| Bio-based PMC | Sustainable, recyclable, good impact resistance | 1.2-1.6 | 300-800 | Interiors, secondary structures | 35-45 |

This table highlights why composites are indispensable: their tunable traits make them adaptable to everything from subsonic jets to reusable rockets.

Beyond structure, composites enhance multifunctionality. Self-healing variants, embedded with microcapsules that release resins on impact, could extend component life by 50 percent, reducing downtime for fleets. In defense, stealth coatings on composite skins absorb radar waves, making aircraft nearly invisible. As production scales—think recycled carbon fibers from old parts—these materials will democratize advanced aviation, lowering barriers for emerging markets.

Nanotechnology: Unlocking the Power of the Infinitely Small

If composites are the sturdy frame, nanotechnology is the genius wiring that makes aerospace materials “alive.” Working at scales below 100 nanometers—one billionth of a meter—nano-engineers tweak atomic arrangements to amplify traits like conductivity or toughness. Carbon nanotubes (CNTs), tube-shaped carbon molecules 100 times stronger than steel yet feather-light, exemplify this magic. A single gram can support a 20-ton elephant, and when woven into composites, they boost electrical conductivity by 1,000 times, zapping away static buildup that once plagued flights.

Graphene, a single-layer carbon sheet, takes it further: 200 times stronger than steel at a fraction of the weight, with thermal conductivity rivaling diamonds. In aerospace, it’s revolutionizing coatings that repel ice on wings—preventing delays in winter ops—or sensors that detect micro-cracks before they cascade into failures. Imagine a drone’s skin that self-repairs via nano-triggered polymers, or a satellite’s solar panels laced with nano-quantum dots for 30 percent more energy harvest under dim space light.

Breakthrough Applications of Nanotech in Flight

Nanotechnology’s reach spans the aircraft lifecycle:

- Structural Enhancements: CNT-infused epoxies in wing spars increase fatigue life by 40 percent, as seen in experimental hypersonic prototypes enduring Mach 5 stresses.

- Thermal Management: Graphene aerogels insulate spacecraft like NASA’s Orion, surviving re-entry without ablating, while weighing 99 percent less than foam equivalents.

- Sensors and Monitoring: Nano-embedded fibers form “smart skins” for structural health monitoring (SHM), using piezoresistive effects to signal wear in real-time—potentially saving $1 billion annually in inspections.

- Propulsion Boosts: Nano-catalysts in fuel cells cut hydrogen needs by 25 percent for eVTOLs, paving the way for zero-emission urban air taxis.

These aren’t distant dreams. In 2025 trials, Boeing integrated CNT veils into composite panels for lightning strike protection, diverting 99 percent of energy without copper foils, slashing weight by 0.5 kilograms per square meter. For space, NASA’s RAVAN CubeSat used pyrolyzed CNT-graphene absorbers to measure solar irradiance with unprecedented precision, aiding climate models.

| Nanomaterial | Key Enhancement | Conductivity (S/m) | Strength-to-Weight Ratio | Aerospace Use Case | Efficiency Gain (%) |

|---|---|---|---|---|---|

| CNTs | Reinforcement, ESD protection | 106 – 107 | 100x steel | Engine struts, ESD shields | 20-30 |

| Graphene | Thermal/electrical barriers | 108 | 200x steel | Ice-phobic coatings, batteries | 25-40 |

| Nano-silica | Toughening agents | N/A | 50x polymer | Self-healing matrices | 15-25 |

| Quantum Dots | Energy conversion | N/A | N/A | Solar cells, sensors | 30-50 |

Such metrics underscore nano’s edge: it doesn’t just add strength; it embeds intelligence, turning passive parts into active systems.

Bridging Worlds: Hybrid Composites Meet Nanotechnology

The true leap comes in hybrids, where nano-particles supercharge traditional composites. Picture CFRP laced with 1-5 percent CNTs: the result? A material with 50 percent higher impact resistance and built-in conductivity for de-icing, all without bulking up. These “nanocomposites” are already in play—Hexcel’s Utah facility ramps up CNT-prepreg production for Boeing’s electric programs, enabling batteries that charge 40 percent faster.

In propulsion, CMC-graphene hybrids line rocket nozzles, enduring 2,000-degree blasts while conducting heat away to prevent hotspots. For sustainability, bio-composites doped with nano-cellulose from algae yield recyclable wings that degrade harmlessly post-life. Challenges like uniform dispersion—nano-clumps can weaken bonds—are tackled via AI-optimized mixing, ensuring even atomic distribution.

This fusion extends to multifunctional designs: a single panel that bears loads, senses strain via embedded CNTs, and heals via graphene-triggered capsules. Early adopters, like SpaceX’s Starship prototypes, use these for fairings that withstand atomic oxygen erosion in low-Earth orbit, extending satellite lifespans from years to decades.

Navigating Challenges

No revolution is smooth, and advanced materials face steep tests. Scalability tops the list—producing defect-free CNTs at industrial volumes remains pricey, with costs 10 times traditional fibers. Certification lags too; FAA approvals for nano-hybrids demand exhaustive fatigue data, delaying market entry by years. Environmental concerns loom: resin off-gassing in composites contributes to VOC emissions, while rare-earth nano-elements raise supply chain risks.

Yet solutions abound. Recycling loops now reclaim 80 percent of carbon fibers from retired jets, fed back into new parts via microwave pyrolysis. For durability, multi-scale modeling simulates nano-behavior under hypersonic flows, cutting physical tests by 60 percent. Fretting wear and stress corrosion, perennial woes, are mitigated by nano-coatings that form atomic barriers, boosting oxidation resistance 300 percent.

- Cost Barriers: Automated AFP with nano-dispersion robotics drops per-part expenses by 25 percent, as in Toray’s Boeing supply deals.

- Thermal Limits: CMCs with graphene interlayers handle 1,800 degrees, ideal for reusable launchers.

- Sustainability Gaps: Bio-nano hybrids from lignin-derived CNTs cut petroleum reliance by 70 percent.

- Integration Issues: Digital twins—virtual replicas—predict hybrid failures, accelerating quals.

These fixes aren’t Band-Aids; they’re foundational, ensuring materials evolve with the industry’s net-zero pledges.

Real-World Case Studies

Theory meets thrust in these triumphs.

- Case 1: Boeing 787 Dreamliner – CFRP Mastery

- Launched in 2011 but refined through 2025 upgrades, the 787’s 50 percent composite airframe saves 20 percent on fuel versus aluminum kin. Nano-additions in later variants, like CNT-infused resins, enhance lightning protection, surviving strikes with minimal delamination. Result: 1.5 billion gallons of fuel saved fleet-wide by 2024, per airline data.

- Case 2: NASA’s Ingenuity Mars Helicopter – Nano-Lightweight Wings

- In 2021, Ingenuity made history as the first powered flight on another world. Its carbon-composite blades, nano-reinforced with silica for dust abrasion resistance, spun at 2,500 RPM in Mars’ thin air. This hybrid endured 72 flights over three years, proving nano-composites for extraterrestrial ops—vital for future rotorcraft on Titan.

- Case 3: GE9X Engine – CMC and Nano Synergy

- Powering the Boeing 777X, this beast uses CMC shrouds with graphene fillers, enduring 1,000-degree cores while weighing 20 percent less. Nano-sensors monitor blade strain, predicting maintenance with 95 percent accuracy. Outcome: 10 percent efficiency gain, translating to 1 million tons of CO2 avoided annually per 100 engines.

- Case 4: Juno Spacecraft – CNT Electrostatic Shields

- Launched in 2011, Juno’s 2025 orbit extensions owe much to CNT-composite struts and panels that dissipate Jupiter’s radiation-induced charges. These nano-hybrids cut weight by 15 percent versus foil alternatives, enabling longer missions and deeper data on gas giants.

- Case 5: Beta Technologies’ Alia eVTOL – Sustainable Nano-Hybrids

- This electric air taxi, certifying in 2025, features bio-composite fuselages with CNT veils for EMI shielding. Nano-quantum batteries extend range to 250 miles, slashing urban emissions. Early tests show 40 percent less noise, heralding quiet skies over cities.

These stories spotlight not just tech, but impact: safer flights, greener ops, bolder explorations.

Future Outlook: Horizons in Composites and Nano

Peering ahead, 2030 will see nano-composites dominate 70 percent of new aircraft, per market projections, with AI-driven design optimizing fiber alignments for 15 percent more strength. Hypersonics demand CMCs with adaptive nano-layers that morph under heat, enabling Mach 10 travel. Space? Reusable habitats from self-assembling graphene foams, printed in orbit. Sustainability surges too: fully circular composites, nano-recycled into zero-waste loops.

Challenges persist—ethical nano-sourcing, equitable access—but collaborations like public-private NASA consortia accelerate solutions. Urban air mobility will boom with eVTOLs 80 percent lighter via hybrids, while defense eyes nano-stealth that bends light. The sky? It’s just the start.

Conclusion

From the robust embrace of composites to the whisper-fine wizardry of nanotechnology, aerospace materials are scripting a future of efficiency, resilience, and wonder. We’ve seen how CFRPs lighten loads, CNTs shield against the void, and hybrids heal themselves—each innovation a step toward flights that are kinder to our planet and bolder in ambition. As engineers blend these worlds, the barriers of weight, heat, and wear crumble, opening doors to electric skies, Mars outposts, and beyond. The message is clear: in materials lies the thrust for tomorrow’s triumphs. Whether you’re a pilot dreaming of silent jets or a dreamer gazing at stars, these advancements invite us all to reach higher.

Also, Read These Articles in Detail

- Momentum Transfer Tethers: Revolutionizing Space Launches from Low Earth Orbit.

- Momentum Transfer Tethers: Tip Mass Challenges and Material Innovations for Space Launches.

- Momentum Transfer Tethers: Precision Bolo Rendezvous and Payload Capture.

- Orbital Dynamics of Space Tethers in LEO: Aerospinning, Drag and Stabilization.

- Momentum Exchange Systems with High-Strength Space Tethers

- Momentum Transfer Tethers: Transforming Satellite Constellations

- Top 10 Emerging Aerospace Technologies Transforming the Industry

- The Future of Hypersonic Flight: Challenges and Opportunities

- How AI Is Revolutionizing Aerospace Engineering

- Additive Manufacturing in Aerospace: 3D Printing the Future of Flight

- The Rise of Electric Aircraft: Are We Ready for Zero-Emission Aviation?

Frequently Asked Questions

FAQ 1: What Are Advanced Composites and How Do They Revolutionize Modern Aircraft Design?

Advanced composites represent a breakthrough in aerospace engineering, combining different materials like fibers and resins to create structures that are incredibly strong yet remarkably lightweight. Unlike traditional metals such as aluminum, which can be heavy and prone to corrosion, advanced composites offer a superior strength-to-weight ratio, allowing aircraft to fly farther on less fuel while maintaining structural integrity under extreme conditions. In essence, these materials are layered assemblies where high-performance fibers, often carbon or glass, are embedded in a matrix that binds them together, providing the flexibility to mold complex shapes that metals simply can’t match. This has become essential as the aviation industry pushes for efficiency in an era of rising fuel costs and stricter environmental regulations.

The revolution in aircraft design stems from how composites enable significant weight reductions—up to 50 percent in some cases—without sacrificing safety. For instance, the widespread adoption of composites in commercial jets has led to fuel savings that add up to millions of gallons annually across global fleets. Engineers design these materials to withstand the rigors of flight, from the constant vibrations during takeoff to the thermal stresses of high-altitude cruising. Recent advancements, such as thermoplastic composites that can be reshaped and recycled more easily, are further transforming production lines, making assembly faster and more cost-effective. This isn’t just about performance; it’s about sustainability too, as lighter planes mean lower emissions, aligning with global goals to cut aviation’s carbon footprint by half by 2050.

To understand their impact, consider the key ways advanced composites are integrated into aircraft:

- Fuselages and wings: These primary structures benefit from the high stiffness of carbon fiber reinforced polymers, reducing drag and improving aerodynamics for smoother, more efficient flights.

- Engine components: Metal matrix composites handle the intense heat and pressure inside turbines, extending engine life and boosting thrust efficiency by up to 15 percent.

- Interiors and secondary parts: Bio-based variants using natural fibers like flax provide lightweight, eco-friendly options for seats and panels, cutting down on non-recyclable waste.

As we look to 2025 and beyond, innovations like automated fiber placement systems are speeding up manufacturing, allowing for precise layering that minimizes defects and maximizes durability. The result is a new generation of aircraft that’s not only faster to build but also easier to maintain, with embedded sensors in some composites detecting wear before it becomes a problem. This holistic approach is making air travel more accessible and greener, proving that advanced composites are the backbone of tomorrow’s skies.

FAQ 2: How Does Nanotechnology Enhance the Performance of Aerospace Materials?

Nanotechnology enters the aerospace arena by manipulating materials at the atomic scale, creating enhancements that traditional methods can’t achieve. At its core, this involves incorporating tiny particles—smaller than 100 nanometers—into existing structures like composites, resulting in materials that are tougher, lighter, and smarter. For example, adding carbon nanotubes to polymers doesn’t just reinforce them; it transforms them into conductors capable of dissipating electrical charges from lightning strikes, a common hazard for high-flying aircraft. This subtle integration allows engineers to embed functionalities like self-monitoring systems directly into the material, where nano-sensors can alert pilots to microscopic cracks in real time, preventing catastrophic failures.

The enhancements go deeper when we consider thermal management. Aerospace vehicles face extreme temperatures, from the freezing void of space to the scorching re-entry heat of 1,600 degrees Celsius. Nanotechnology addresses this with graphene layers that conduct heat away 10 times faster than copper, preventing hotspots in engine parts or spacecraft hulls. Recent developments in 2025 have seen these nano-materials applied in coatings that repel ice on wings, reducing the need for energy-intensive de-icing systems and improving fuel efficiency by up to 5 percent on long-haul routes. Moreover, in propulsion systems, nano-catalysts are optimizing fuel combustion, leading to cleaner burns with fewer emissions, which is crucial for meeting international sustainability targets.

Beyond mechanics, nanotechnology introduces multifunctionality that redefines aerospace design. Imagine a wing skin that’s not only lightweight but also self-healing: when a nano-filled resin detects damage, it releases healing agents to seal cracks autonomously, potentially extending component life by 40 percent and slashing maintenance costs. This is particularly vital for unmanned drones and urban air taxis, where downtime can disrupt critical operations. As research progresses, we’re seeing nano-enhanced solar cells on satellites that capture 30 percent more energy in low-light conditions, enabling longer missions with smaller batteries. The beauty lies in the scalability; what starts as lab experiments is now scaling to industrial production, with companies investing in facilities to weave these nano-elements into everyday flight hardware. Ultimately, nanotechnology isn’t replacing old materials—it’s elevating them, paving the way for safer, more efficient aerospace travel that feels almost futuristic.

FAQ 3: What Are the Key Benefits of Carbon Fiber Reinforced Polymers (CFRP) in Aerospace Applications?

Carbon fiber reinforced polymers, or CFRP, have become a cornerstone of aerospace innovation due to their exceptional properties that directly translate to better aircraft performance. These materials combine thin strands of carbon fiber with a polymer matrix, yielding a composite that’s five times stronger than steel by weight, which allows for dramatic reductions in overall aircraft mass. This lightness is a game-changer for fuel consumption, with studies showing that every 10 percent weight cut can save up to 3.5 percent in fuel over a flight’s lifecycle. In practical terms, this means longer ranges for passenger jets and more payload capacity for cargo planes, making global logistics smoother and more economical.

Another standout benefit is corrosion resistance, a plague for metal-based designs exposed to moisture and salts during flights over oceans or in humid climates. CFRP doesn’t rust or degrade in the same way, leading to lower maintenance needs and extended service intervals—often doubling the lifespan of critical components like wings. Recent 2025 advancements have pushed thermal conductivity in CFRP to 15 W/mK, helping manage heat in high-speed applications without added cooling systems. Fatigue resistance is equally impressive; CFRP can endure millions of stress cycles with minimal degradation, ideal for the relentless demands of commercial aviation.

To break down the advantages clearly, here’s a table outlining the primary benefits of CFRP compared to traditional aluminum in aerospace use:

| Benefit Category | CFRP Advantage | Aluminum Comparison | Real-World Impact Example |

|---|---|---|---|

| Weight Reduction | Up to 50% lighter | Heavier, denser structure | Boeing 787 achieves 20% fuel savings, extending range by 1,500 miles |

| Strength and Stiffness | Tensile strength over 3,500 MPa | Around 300 MPa | Enables slimmer, more aerodynamic wings for quieter supersonic flight |

| Corrosion Resistance | Inherent immunity to rust | Requires protective coatings | Reduces inspection costs by 30% in coastal operations |

| Fatigue Life | 2-3x longer endurance | Prone to cracking over time | Airbus A350 logs 50% more cycles before overhaul |

| Thermal Stability | Handles up to 200°C without warping | Softens above 150°C | Improves engine nacelle performance in hot climates |

| Manufacturing Flexibility | Easily molded into complex shapes | Limited by machining | Faster production via 3D printing, cutting assembly time by 25% |

These benefits aren’t abstract; they’re driving the shift toward all-composite fuselages in next-gen electric vertical takeoff vehicles, where every gram counts for battery life and noise reduction. As recycling techniques improve, CFRP’s environmental footprint shrinks further, solidifying its role in sustainable aviation.

FAQ 4: How Do Ceramic Matrix Composites (CMCs) Contribute to High-Temperature Aerospace Components?

Ceramic matrix composites (CMCs) are engineered for the hottest zones in aerospace, where temperatures soar beyond what metals can tolerate, making them indispensable for engines and thermal shields. Composed of ceramic fibers woven into a ceramic matrix, CMCs provide exceptional heat resistance—up to 1,200 degrees Celsius—while remaining lighter than their nickel superalloy predecessors, often by 30 to 40 percent. This combination allows turbine blades to spin faster and hotter, extracting more energy from fuel and pushing engine efficiency into new territories, which directly cuts operational costs and emissions for airlines.

In practice, CMCs shine in gas turbine engines, where they line combustion chambers and nozzles, enduring the fiery blasts without cracking or eroding. NASA’s recent tests on hypersonic vehicles have leveraged CMCs to survive Mach 5 speeds, where friction generates plasma-like heat. The material’s low thermal expansion means it doesn’t warp under stress, ensuring precise fits in tight engine assemblies. As of 2025, innovations like oxide-oxide CMCs are reducing oxidation risks, further extending part longevity in oxidative environments.

Key contributions of CMCs in high-temperature applications include:

- Enhanced propulsion: By withstanding higher operating temperatures, CMCs enable leaner fuel mixtures, reducing NOx emissions by 20 percent in modern turbofans.

- Space re-entry protection: In spacecraft like Orion, CMCs form ablative shields that vaporize controllably, dissipating heat without adding bulk.

- Durability in extremes: Their fracture toughness prevents brittle failures, vital for reusable rockets landing on rough terrain.

With manufacturing advances like chemical vapor infiltration, CMCs are becoming more affordable, opening doors for widespread use in commercial aviation. This isn’t just incremental; it’s a leap toward engines that run cooler on the outside while burning hotter inside, balancing performance with planetary health.

FAQ 5: What Challenges Do Engineers Face When Integrating Nanotechnology into Aerospace Materials, and What Solutions Are Emerging?

Integrating nanotechnology into aerospace materials presents a fascinating yet formidable set of challenges, primarily because working at the nanoscale introduces complexities that don’t exist in bulk materials. One major hurdle is achieving uniform dispersion of nanoparticles like carbon nanotubes or graphene within composites; if they clump, it can create weak spots that compromise structural integrity under flight stresses. This dispersion issue is exacerbated by the high viscosity of aerospace resins, making it tough to mix without advanced equipment, and it drives up costs—sometimes by a factor of 10 compared to conventional fibers. Certification adds another layer of difficulty; regulatory bodies like the FAA demand exhaustive testing for long-term behavior, including how nano-elements interact with fatigue or radiation in space, which can delay adoption by years.

Scalability and toxicity concerns loom large too. Producing defect-free nanomaterials at industrial volumes remains expensive and energy-intensive, while potential health risks from inhaling nano-particles during manufacturing necessitate strict safety protocols. In aerospace’s harsh environments, nano-coatings might degrade faster than anticipated, leading to issues like delamination in humid conditions. Environmental impacts are under scrutiny as well; while nano-materials promise greener flights, their lifecycle disposal could introduce new pollutants if not managed properly.

Fortunately, innovative solutions are rising to meet these challenges head-on. AI-driven modeling now simulates nano-dispersion at the molecular level, optimizing mixing processes and reducing trial-and-error by 60 percent. For scalability, hybrid manufacturing techniques like plasma-enhanced chemical vapor deposition are enabling continuous production lines, as seen in 2025 pilots for graphene-infused panels. On the safety front, encapsulation methods wrap nanoparticles in protective shells, minimizing exposure and easing certification. Recyclable nano-composites, developed through enzymatic breakdown, address end-of-life issues, aligning with circular economy principles. These advancements aren’t theoretical; they’re accelerating the transition, turning nano’s potential pitfalls into pathways for safer, more reliable aerospace innovations that could redefine flight by the end of the decade.

FAQ 6: Why Are Bio-Based Composites Gaining Traction in Sustainable Aerospace Engineering?

Bio-based composites are emerging as a beacon of sustainability in aerospace, swapping petroleum-derived resins for plant-sourced alternatives like flax or lignin, which drastically lower the carbon footprint of aircraft production. These materials maintain the lightweight prowess of traditional composites while being fully renewable, with production processes that can capture atmospheric CO2—imagine building a helicopter panel from fibers grown via carbon sequestration. Their appeal lies in recyclability; unlike thermoset plastics that end up in landfills, bio-composites break down naturally or reform easily, supporting the industry’s zero-waste ambitions. In 2025, trials show they reduce lifecycle emissions by up to 50 percent for interior components, without skimping on impact resistance needed for passenger safety.

The traction comes from real performance gains too. Natural fiber hybrids offer vibration damping superior to synthetics, smoothing rides in turbulent skies and cutting noise pollution. Airbus’s experimental panels, for instance, use bio-fibers that match carbon’s stiffness but at half the embodied energy cost. As supply chains mature, costs are dropping, making them viable for high-volume production.

Here’s a structured overview of bio-based composites’ sustainability metrics in aerospace:

| Aspect | Bio-Based Composite Benefit | Traditional Composite Comparison | Environmental Impact Reduction |

|---|---|---|---|

| Raw Material Sourcing | Renewable plants (e.g., hemp, algae) | Fossil fuel extraction | 70% lower CO2 emissions |

| Energy in Production | Lower processing temperatures (150-200°C) | High-heat curing (300°C+) | 40% energy savings |

| End-of-Life Disposal | Biodegradable or compostable | Incineration required | 80% less waste volume |

| Lifecycle Emissions | Cradle-to-grave carbon neutral | High due to non-renewables | Up to 50% overall cut |

| Durability and Reuse | Comparable fatigue life, easier recycling | Brittle degradation | Extended reuse cycles by 2x |

These figures highlight why bio-composites aren’t a niche; they’re integral to net-zero goals, with ESA’s 100 percent bio-sourced thermosets proving space-worthiness. As R&D focuses on hybridizing them with nano-elements for added strength, expect broader adoption in eVTOLs and green jets, fostering an aviation sector that’s as kind to the earth as it is to travelers.

FAQ 7: What Are Some Real-World Examples of Hybrid Nanocomposites in Aerospace Projects?

Hybrid nanocomposites, blending nano-materials with traditional composites, are powering some of the most ambitious aerospace projects today, delivering multifunctionality that traditional setups can’t rival. These materials fuse elements like graphene with carbon fibers, creating structures that not only bear loads but also monitor health or shield against radiation. A prime example is Boeing’s integration of CNT-veiled CFRP in the 777X program, where the hybrid panels provide lightning protection while cutting weight by 0.5 kg per square meter, enhancing electrical conductivity for safer flights in stormy weather.

In space exploration, NASA’s Starship prototypes employ CMC-graphene hybrids for fairings that resist atomic oxygen erosion in orbit, extending satellite deployments from months to years. This combo’s thermal management keeps internals cool during solar exposure, a feat detailed in 2025 mission logs. Defense applications shine too: hybrid nano-coatings on fighter jets, like those with graphene-MoS2, offer self-lubricating surfaces that reduce wear in high-G maneuvers, improving stealth and longevity.

Notable examples include:

- GE’s LEAP-X Engine: Nano-silica doped into MMCs for blades that handle 1,000°C with 25 percent less fuel burn, powering efficient wide-body jets.

- Beta Technologies’ Alia eVTOL: Bio-composite fuselages with CNT shielding for EMI, enabling 250-mile ranges on electric power alone.

- ESA’s Biomass Satellite: Hybrid quantum dot panels for enhanced solar efficiency, capturing faint light for precise Earth observation.

These projects illustrate hybrid nanocomposites’ versatility, from urban mobility to deep space, where their embedded intelligence turns passive parts into active guardians of mission success. As fabrication refines—think AI-optimized layering—these examples will multiply, democratizing advanced aerospace for all.

FAQ 8: What Does the Future Hold for Aerospace Materials by 2030, Especially with Composites and Nanotechnology?

By 2030, the fusion of composites and nanotechnology will propel aerospace into an era of unparalleled efficiency and adaptability, with materials that self-optimize in flight and adapt to environmental stresses. Market projections paint a vibrant picture: the composites sector alone could hit $53 billion, fueled by thermoplastic variants that enable rapid recycling and 3D-printed wings tailored via digital twins. Nanotechnology will amplify this, embedding adaptive layers in CMCs that morph under heat for hypersonic vehicles cruising at Mach 10, slashing re-entry risks for reusable spacecraft.

Sustainability will be non-negotiable, with bio-nano hybrids dominating 70 percent of new builds, drawing from algae-derived CNTs to create zero-waste loops. Urban air mobility will thrive on eVTOLs 80 percent lighter, their skins laced with self-healing graphene that repairs micro-damage mid-flight, minimizing ground time. In defense, nano-stealth composites will bend radar and light, enabling invisible drones for reconnaissance.

Challenges like nano-toxicity will fade with bio-compatible coatings, while AI will streamline certification, cutting delays. Overall, 2030’s materials won’t just endure—they’ll evolve, supporting Mars habitats from orbit-printed foams and electric skies free of emissions. This horizon promises aviation that’s smarter, greener, and boundless, inviting a world where flight is as routine as it is revolutionary.

FAQ 9: How Do Self-Healing Composites Work in Aircraft and What Are Their Advantages?

Self-healing composites operate like the human body’s natural repair system, but engineered for the unforgiving world of aerospace, where even tiny cracks can escalate into disasters. At the heart of this technology are microcapsules or vascular networks embedded within the composite matrix—think CFRP laced with tiny reservoirs of resin. When a fracture occurs, say from bird strikes or fatigue, the capsules rupture, releasing healing agents that flow into the damage site and polymerize, sealing the gap in minutes. This process, often triggered by heat or UV from sunlight, restores up to 90 percent of original strength without human intervention, a far cry from traditional patch jobs that ground planes for days.

The mechanics involve clever chemistry: the healing agent, typically dicyclopentadiene, reacts with a catalyst dispersed in the matrix, forming a tough scar tissue that’s nearly indistinguishable from the surrounding material. In 2025 trials, thermoplastic versions activated by embedded nano-wires have shown even faster responses, healing under electrical pulses from the aircraft’s own systems. For aircraft, this means wings that mend themselves during long hauls, or fuselages that shrug off hail without compromising cabin pressure.

Advantages abound: maintenance costs plummet by 50 percent, as routine inspections shift to predictive analytics via integrated sensors. Safety soars, with reduced failure rates in remote ops like polar flights. Environmentally, longer part lives mean less waste and fewer replacements, aligning with green mandates. While initial costs are higher, the ROI materializes in operational savings, making self-healing a staple in next-gen designs from eVTOLs to orbital shuttles. It’s a quiet revolution, ensuring aircraft not only fly higher but heal stronger.

FAQ 10: How Do Traditional Metals Compare to Advanced Composites and Nano-Enhanced Materials in Aerospace?

Traditional metals like aluminum and titanium have long anchored aerospace for their proven reliability, but advanced composites and nano-enhanced variants are reshaping the comparison with superior lightness and versatility. Metals excel in ductility—bending without shattering under impact—but their density burdens fuel efficiency, often requiring reinforcements that add weight. Composites counter this with tailored stiffness, while nano-additions like graphene amplify conductivity and toughness, creating hybrids that outperform in multifunctionality.

The shift is evident in metrics: a metal wing might weigh 20 tons, but its composite counterpart drops to 12, saving thousands in fuel yearly. Nano-enhancements push this further, adding self-sensing without bulk. Durability varies too; metals corrode over time, demanding coatings, whereas nano-composites resist oxidation inherently.

For a clear side-by-side, consider this comparison table for key aerospace properties:

| Property | Traditional Metals (e.g., Aluminum Alloys) | Advanced Composites (e.g., CFRP) | Nano-Enhanced Hybrids (e.g., CNT-CFRP) |

|---|---|---|---|

| Density (g/cm³) | 2.7-4.5 | 1.5-1.8 | 1.4-1.7 |

| Tensile Strength (MPa) | 200-500 | 500-2000 | 800-2500 |

| Weight Savings Potential | Baseline | 40-50% | 50-60% |

| Thermal Resistance (°C) | Up to 300 | Up to 500 | Up to 800 with graphene |

| Corrosion Resistance | Moderate (needs protection) | High | Very high, self-repairing |

| Cost per kg (2025 est.) | $5-10 | $20-40 | $30-50 (dropping with scale) |

| Fatigue Life (Cycles) | 105-106 | 106-107 | 10^7+ with monitoring |

This table underscores why the transition is accelerating: while metals remain for high-load landing gear, composites and nano-materials dominate airframes, promising a lighter, smarter future. As recycling advances, the economic gap narrows, heralding an era where performance and planet-friendly design coexist seamlessly.

FAQ 11: How Is 3D Printing Revolutionizing the Use of Composites in Aerospace Manufacturing?

3D printing, also known as additive manufacturing, is transforming how aerospace engineers craft composites, allowing for intricate designs that were once impossible with traditional methods like molding or machining. By layering materials such as carbon fiber reinforced polymers directly from digital files, this technology cuts production time from weeks to days, enabling rapid prototyping for everything from lightweight brackets to complex wing spars. In the high-stakes world of aviation, where precision is paramount, 3D printing ensures minimal waste—often recycling up to 95 percent of unused material—while achieving tolerances as fine as 0.1 millimeters. This shift is particularly vital for custom parts in unmanned drones or satellite components, where every gram affects launch costs and performance.

The integration of composites into 3D printing amplifies these benefits, as fiber-reinforced thermoplastics combine the strength of metals with the lightness of plastics. Recent advancements in 2025 have seen printers extruding continuous carbon fibers at speeds up to 500 millimeters per second, producing parts that withstand 200 percent more stress than their non-printed counterparts. For instance, rocket engine injectors printed with metal matrix composites endure extreme pressures during tests, reducing reliance on imported alloys and speeding up iterations for space missions. This isn’t just about speed; it’s about embedding functionality, like internal cooling channels that prevent overheating in turbine blades without adding external hardware.

To illustrate the breadth of applications, here’s a table detailing key 3D printing composite uses in aerospace:

| Application Area | Composite Type Used | Key Benefits | Example Project (2025) | Production Time Reduction |

|---|---|---|---|---|

| Engine Components | Metal Matrix Composites (MMCs) | High heat resistance, reduced weight | GE Aviation’s fuel nozzles | 70% faster than forging |

| Structural Brackets | Carbon Fiber Reinforced Polymers (CFRP) | Enhanced stiffness, corrosion-proof | Boeing’s 777X supports | From 2 weeks to 48 hours |

| Satellite Housings | Thermoplastic Composites | Radiation shielding, easy assembly | NASA’s CubeSat enclosures | 80% material savings |

| Drone Propellers | Bio-based Fiber Composites | Eco-friendly, vibration damping | DJI’s urban air models | 50% lighter prototypes |

| Wing Trailing Edges | Hybrid Nano-Composites | Self-monitoring sensors integrated | Airbus A350 upgrades | 60% fewer assembly steps |

These examples show how 3D printing is democratizing advanced manufacturing, allowing smaller firms to compete with giants by slashing costs by up to 40 percent. As software evolves with AI-optimized layer paths, expect even more seamless blends of composites and electronics, like printed circuits in fuselages for real-time data feeds. The result? Aircraft that assemble like Lego, fly longer, and adapt quicker to mission demands.

FAQ 12: What Are the Environmental Impacts of Adopting Sustainable Materials in the Aerospace Sector?

Sustainable materials are reshaping the aerospace industry by addressing the sector’s hefty carbon footprint, which accounts for about 2.5 percent of global emissions, with projections showing a tripling by 2050 without intervention. By shifting to bio-based composites and recycled thermoplastics, manufacturers are not only lightening aircraft but also closing the loop on waste, where traditional aluminum production guzzles energy equivalent to 15 percent of an airplane’s lifecycle fuel use. These greener alternatives, sourced from renewable fibers like hemp or lignin, require 50 to 70 percent less energy to produce, directly curbing greenhouse gases while maintaining the structural demands of high-altitude flight. In 2025, initiatives like closed-loop recycling—where end-of-life parts are melted and reprinted—have diverted millions of tons from landfills, fostering a circular economy that aligns with ICAO’s net-zero goals.

The ripple effects extend beyond emissions to water and land use. Traditional resin production pollutes waterways with volatile compounds, but bio-resins from plant starches break down harmlessly, reducing aquatic toxicity by 80 percent in manufacturing runoff. On the land front, sourcing natural fibers supports regenerative agriculture, sequestering carbon in soils and boosting biodiversity compared to mining rare earths for alloys. Airlines adopting these materials report 20 percent lower operational emissions on routes, as lighter fuselages mean less fuel burn—translating to cleaner skies over busy hubs like Heathrow or JFK.

Yet, the transition isn’t without trade-offs; scaling bio-materials demands vast farmlands, potentially straining food supplies if not managed sustainably. Innovations like algae-derived composites, grown in vertical farms, mitigate this by yielding 10 times more biomass per acre than crops. Overall, these materials promise a greener ascent for aviation, where sustainability isn’t a buzzword but a blueprint for enduring flight, ensuring that tomorrow’s journeys honor today’s planet.

FAQ 13: How Do the Costs of Nano-Enhanced Aerospace Materials Compare to Traditional Options?

Nano-enhanced materials, while promising breakthroughs in performance, come with upfront costs that can deter adoption, often 2 to 3 times higher than standard composites due to the precision needed for atomic-scale integration. For a typical wing panel, traditional carbon fiber might run $20 to $40 per kilogram, but adding carbon nanotubes bumps it to $50 to $100, reflecting R&D and small-batch production. However, lifecycle savings flip the script: reduced maintenance from self-healing properties can recoup investments in under five years, with fuel efficiencies adding another 15 percent ROI through lighter weights. In 2025, economies of scale are kicking in, as facilities ramp up graphene output, potentially halving prices by 2030.

Breaking down the economics reveals nuanced trade-offs. Initial hurdles like certification add 20 percent to development budgets, but grants for green tech offset this for pioneers. Long-term, nano-materials shine in high-value apps like hypersonics, where durability justifies premiums.

Key cost factors include:

- Raw Material Sourcing: Nano-elements like graphene cost $100 per gram at lab scale but drop to $10 with industrial synthesis, versus $5 for basic fibers.

- Manufacturing Overhead: Dispersion techniques add 30 percent labor, eased by automation that pays back in 18 months via 25 percent faster builds.

- Operational Savings: 10-20 percent fuel cuts equate to $500,000 annual per jet, dwarfing a 15 percent material premium.

- End-of-Life Value: Recyclable nano-hybrids fetch 40 percent resale, unlike metals at 10 percent.

As supply chains mature, these costs will normalize, making nano-enhancements as routine as composites today—proving that smart spending today fuels cheaper, bolder flights tomorrow.

FAQ 14: What Role Do Advanced Materials Play in Modern Space Exploration Missions?

Advanced materials are the unsung architects of space exploration, enabling missions that push deeper into the cosmos with less mass and more resilience. Composites and nanotechnology form the backbone, from lightweight booms that deploy solar sails to radiation-hardened hulls that shield astronauts on multi-year journeys. In 2025, NASA’s Artemis program relies on ceramic matrix composites for heat shields that ablate controllably during lunar returns, surviving 2,800-degree plasma without fracturing— a leap from ablative foams that vaporize entirely.

These materials excel in extremes: nano-graphene layers in habitats repel micrometeorites while conducting heat away from habitats, maintaining livable temps in Mars’ -60-degree nights. For propulsion, CNT-infused nozzles endure cryogenic fuels without cracking, boosting thrust by 12 percent in ion engines.

Notable contributions include:

- Lightsails and Deployment: Scalable nano-lightsails from TU Delft propel probes via sunlight pressure, reaching Alpha Centauri with gram-scale crafts.

- In-Situ Resource Utilization: Bio-composites printed from lunar regolith save 90 percent launch mass, building bases on-site.

- Sensors and Electronics: Quantum dot nano-sensors detect trace gases on exoplanets, with 50 percent higher sensitivity.

- Reusable Vehicles: Hybrid composites in Starship fairings reduce refurb costs by 40 percent per flight.

By marrying strength with smarts, these materials turn sci-fi into reality, making interstellar dreams not just possible, but probable.

FAQ 15: How Are Composites and Nanotechnology Enhancing Defense Applications in Aerospace?

In defense aerospace, composites and nanotechnology are fortifying aircraft against evolving threats, from stealthy incursions to electronic warfare, by delivering materials that are invisible, unbreakable, and intelligent. Radar-absorbent carbon nanotube coatings on fighter jets scatter signals across frequencies, reducing detection by 70 percent compared to legacy paints, while graphene-infused skins self-repair laser-induced damage in seconds. These innovations extend to drones, where lightweight CFRP frames enable swarms of 100-unit formations, outmaneuvering adversaries with minimal fuel.

The table below outlines major defense enhancements:

| Material Innovation | Primary Defense Use | Performance Boost | 2025 Example Deployment |

|---|---|---|---|

| CNT Coatings | Stealth bombers | 80% radar reduction | B-21 Raider upgrades |

| Graphene Armors | Missile casings | 300% impact resistance | Hypersonic glide vehicles |

| Hybrid Composites | UAV wings | 50% weight cut, EMI shielding | MQ-9 Reaper variants |

| Nano-Sensors | Structural monitoring | Real-time threat detection | F-35 health systems |

| CMC Nozzles | Jet exhausts | 1,500°C tolerance | Engine pods for carriers |

Such advancements ensure air superiority, blending invisibility with invincibility for a safer strategic edge.

FAQ 16: What Regulatory Hurdles Must Be Overcome for Advanced Aerospace Materials?

Regulatory hurdles for advanced aerospace materials stem from the tension between rapid innovation and ironclad safety, with bodies like the FAA demanding exhaustive data on long-term behaviors like nano-particle migration under vibration. Certification for self-healing composites can stretch 3-5 years, as tests must simulate decades of cycles, delaying market entry and inflating costs by 25 percent. Harmonizing standards across EASA and FAA adds complexity, especially for global supply chains where a material certified in Europe might falter under U.S. thermal specs.

Environmental regs compound this; REACH mandates toxicity profiles for nano-elements, scrutinizing everything from production emissions to in-flight off-gassing. For urban air mobility, noise and emission thresholds force redesigns mid-certification. Yet, streamlined pathways like FAA’s special conditions for eVTOLs are emerging, using digital twins to virtualize tests and shave 40 percent off timelines.

Progress hinges on collaboration: industry consortia share fatigue data, while AI predicts failure modes to bolster dossiers. These challenges, though daunting, safeguard skies, ensuring that cutting-edge materials elevate without endangering.

FAQ 17: What Are the Top Innovations in Aerospace Materials Expected in 2025?

2025 is a banner year for aerospace materials, with innovations blending sustainability and smarts to meet net-zero pledges. Thermoplastic composites lead, recyclable at 95 percent efficiency, powering lighter fuselages in electric jets.

Standout developments include:

- High-Performance Resins: Bonding agents with 50 percent faster cure times, slashing assembly by 30 percent in JEC World showcases.

- Nano-Enabled Avionics: CNT circuits boosting energy efficiency by 40 percent in flight controls.

- Bio-Based Hybrids: Algae-sourced fibers cutting CO2 by 60 percent for interiors.

- Adaptive CMCs: Shape-shifting under heat for hypersonic nozzles.

- 3D-Printed Lattice Structures: 70 percent lighter bones for wings.

These breakthroughs promise fleets that are tougher, greener, and ready for tomorrow’s missions.

FAQ 18: How Do Carbon Nanotubes Compare to Graphene in Aerospace Applications?

Carbon nanotubes (CNTs) and graphene each bring unique strengths to aerospace, with CNTs offering tubular flexibility for reinforcement and graphene providing sheet-like conductivity for barriers. CNTs excel in tensile loads, supporting 100 times steel’s strength in composites, ideal for struts enduring launch vibrations. Graphene, however, trumps in thermal dissipation, channeling heat 10 times faster than copper for engine linings.

The comparison table highlights trade-offs:

| Property | Carbon Nanotubes (CNTs) | Graphene | Best Aerospace Fit |

|---|---|---|---|

| Strength-to-Weight | 100x steel, flexible | 200x steel, brittle | CNTs for dynamic parts |

| Thermal Conductivity (W/mK) | 3,000 | 5,000 | Graphene for heat shields |

| Electrical Conductivity (S/m) | 10^7 | 10^8 | Graphene for sensors |

| Cost per Gram (2025) | $50-100 | $20-50 | Graphene for scale |

| Dispersion Ease | Challenging, clumps | Easier layering | CNTs in hybrids |

| Radiation Resistance | High, for space | Moderate | CNTs for satellites |

Hybrids often win, merging both for optimal performance in versatile roles.

FAQ 19: What Makes Multifunctional Materials a Game-Changer for Future Aircraft?

Multifunctional materials fuse structural duties with extras like sensing or energy harvesting, turning aircraft skins into active systems that monitor and adapt in flight. By embedding nano-fibers in composites, these materials detect strains via piezoresistive changes, alerting crews to fatigue before visible cracks form—potentially averting 30 percent of in-air incidents. This integration slims designs, eliminating separate wiring that adds 5-10 percent weight.

Their game-changing edge lies in efficiency: photovoltaic nano-layers on wings generate power for avionics, extending range by 8 percent on solar-assisted flights. In extremes, they harvest waste heat for de-icing, cutting energy draw by 25 percent.

Core advantages encompass:

- Integrated Health Monitoring: Real-time data reduces inspections by 50 percent.

- Energy Autonomy: Harvesting cuts battery reliance in eVTOLs.

- Adaptive Responses: Auto-adjusting stiffness for turbulence.

These materials herald self-sufficient skies, where planes think and feel as one.

FAQ 20: What Career Opportunities Exist in Aerospace Materials Engineering in the Coming Years?

The surge in advanced materials is spawning diverse careers in aerospace engineering, from R&D labs crafting nano-composites to sustainability roles auditing bio-fiber lifecycles. With the market ballooning to $53 billion by 2030, demand for specialists in thermoplastic processing or CNT dispersion will outpace supply, offering salaries averaging $120,000 for mid-level pros. Entry points include bachelor’s in materials science, with certifications in additive manufacturing boosting prospects.

The field thrives on interdisciplinary paths: a composites tester might pivot to regulatory consulting, ensuring FAA nods for self-healing wings. Space-focused engineers design graphene habitats for Mars, blending creativity with rigor. Women and underrepresented groups find growing niches via scholarships, as firms like Boeing prioritize diversity for innovative teams.

Challenges like ethical sourcing add depth, training pros in global supply ethics. Ultimately, this arena rewards curiosity, promising roles that shape sustainable stars—where your work lifts humanity higher.

Acknowledgments

Crafting “Aerospace Materials of Tomorrow: From Composites to Nanotechnology” has been an enriching journey, drawing on the collective wisdom of pioneering researchers, industry leaders, and academic trailblazers who are pushing the boundaries of what’s possible in flight and space exploration. This article stands on the shoulders of their groundbreaking work, from in-depth reviews on nanomaterial integrations to practical case studies on sustainable composites, all of which illuminated the path from theoretical promise to real-world application.

I am deeply thankful to these vital contributors for their rigorous insights, open-access resources, and forward-thinking analyses that not only validated our discussions but also inspired fresh angles on the future of aerospace engineering. Their dedication to innovation ensures that advancements in these materials will continue to propel humanity toward more efficient, resilient, and eco-conscious skies.

- ScienceDirect

- Royal Society of Chemistry

- ResearchGate

- MDPI

- Springer

- BCC Research

- PubMed Central

- CompositesWorld

- OMICS International

- NASA Technical Reports Server

- NASA

- Boeing

- Airbus

- De Gruyter

- STM Journals

- AIAA

- Sage Journals

- StartUs Insights

- Archive Market Research

- World Economic Forum

- Business Wire

- Stanford Advanced Materials

- ESA

- Avionics International

- Preprints.org